A Look at the Different Densities of 3D Printing Materials

There’s so much to learn about 3D printing materials. Come and find out what to look for when examining the different densities of 3D printing filaments.

844-810-1385

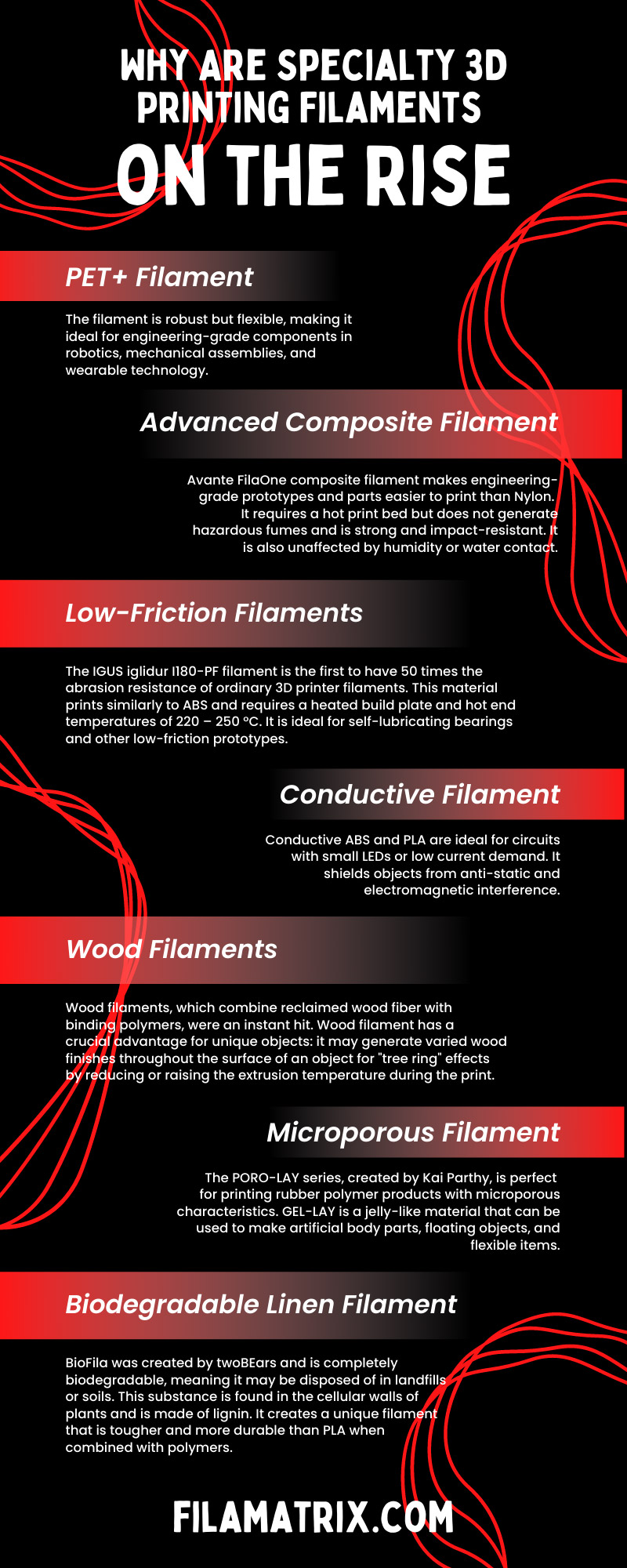

It’s not only about new hues with specialty 3D printing filaments; they’re also about utility. In the field of fused deposition modeling (FDM), the industry is working to develop new filaments that address real-world problems. There’s a filament for everything, whether you’re trying to 3D print sustainable products, make a mold for lost wax casting, or recreate an ancient bronze sculpture. Here are some of the most popular specialty 3D printing filaments and some reasons why these filaments are on the rise!

The latest metal 3D printing filaments are as close to the actual thing as you can get right now. Several businesses have created a class of filaments that closely resemble the appearance of various metals by combining micron-sized metal particles or powder with plastic. One of the first companies to blend PLA plastic with 15% chopped carbon fibers was Proto-Pasta. Carbon Fiber PLA is quite popular because it has a higher stiffness than PLA or ABS. As a result of the team’s success, they’ve added Stainless Steel (PLA plastic with powdered steel) and Magnetic Iron PLA to their product line (ground iron powder with PLA).

Each product blends plastic and powdered metal, allowing users to make items that resemble laser sintered parts. GMASS is a metal 3D printing filament made up of ABS with tungsten or bismuth, and it’s designed for use in desktop 3D printers. Weight, feel, and solidity are among the “metal-like” properties. GMASS is becoming increasingly popular in medical engineering applications, as it’s ideal for athletic equipment, laboratory equipment, vibration dampening, and X-ray shielding. Tuner MedTech developed these filaments, which are used in medical devices. GMASS may also be used to create radiation shielding in 3D.

Metal filaments require a little more attention than PLA or ABS filaments. Brass nozzles are standard on the majority of desktop 3D printers. While metal filaments are functional, they significantly increase wear and tear. Fine metal particles heated, cooled, and pushed through the tip of a brass nozzle will reduce its performance life dramatically. If you plan on printing with metal filaments frequently, stainless steel nozzles are more durable than brass and can better withstand interior abrasion.

Some companies have developed PET+ filament, which combines the printability of PET with the robustness of ABS. The filament is robust but flexible, making it ideal for engineering-grade components in robotics, mechanical assemblies, and wearable technology. When compared to ABS, PET+ can withstand over double the pressure in flexibility strength testing. It’s more flame-resistant than PLA or ABS, and it has good adhesive properties while printing, so it doesn’t require a hot platform.

With Filamatrix’s Zenith copolymer printer filament, you not only gain a durable and flexible material but one that’s very easy for beginners to print with as well. This product also provides excellent bridging and retraction, which is great for reducing the risk of warping. Additionally, our Zenith PETG material has higher heat resistance than standard PLA.

Avante FilaOne composite filament makes engineering-grade prototypes and parts easier to print than Nylon. It requires a hot print bed but does not generate hazardous fumes and is strong and impact-resistant. It is also unaffected by humidity or water contact. To print with FilaOne, you’ll need a particular adhesive surface, which can be purchased separately. This filament has a high rigidity and tensile strength, making it ideal for designing prototypes or parts.

Filamatrix offers a wide range of advanced composite filaments, particularly within the Nylon products. Various forms of Nylon filament are available including high-impact copolymers like Phoenix that make for easier nylon printing, high stiffness Nylon Carbon Fiber filament, and Nylon Hydrophobic which is significantly less sensitive to moisture uptake.

Only at Filamatrix will you find this exclusive Kevlar-filled nylon filament. We’re proud of this tough-as-nails product that delivers high abrasion, heat resistance, high tensile strength, and extreme toughness. Filamatrix Nylon Kevlar 3D printer filament is ideal for repeat-use parts that will see a lot of wear and tear. To yield the best results, read on below to learn the best way to use this durable Kevlar–reinforced nylon filament.

The IGUS iglidur I180-PF filament is the first to have 50 times the abrasion resistance of ordinary 3D printer filaments. This material prints similarly to ABS and requires a heated build plate and hot end temperatures of 220 – 250 °C. It is ideal for self-lubricating bearings and other low-friction prototypes. The I180-PF is frequently utilized in designs that need repetitive movement or in which surface contact

Several businesses have previously released conductive ABS and PLA filament for the electronics industry. Conductive ABS and PLA are ideal for circuits with small LEDs or low current demand. It shields objects from anti-static and electromagnetic interference. Conductive filament is semi-flexible and strong, although it requires more layer adhesion attention than ordinary PLA.

Wood filaments, which combine reclaimed wood fiber with binding polymers, were an instant hit. Wood filament has a crucial advantage for unique objects: it may generate varied wood finishes throughout the surface of an object for “tree ring” effects by reducing or raising the extrusion temperature during the print. Changing the print temperature will provide smoother or rougher surface qualities as a result. Wood filament is relatively simple to print with, requiring only minor modifications in print parameters and no heated bed to produce the required effect. It only slightly warps and can be sanded, ground, stained, or painted afterward. Work within the extrusion temperature ranges; overheated wood filament burns and tars, resulting in severe clogging.

Although these filaments are still in the early stages of development, they are available for purchase. The PORO-LAY series, created by Kai Parthy, is perfect for printing rubber polymer products with microporous characteristics. GEL-LAY is a jelly-like material that can be used to make artificial body parts, floating objects, and flexible items. Soft rubber applications such as sponges, micro-foam, elastics, and ink-absorbing material benefit from LAY-FOMM. PVA and rubber-elastomeric polymers are used to create these products. The PVA in the model vanishes after it is submerged in water. As a result, the object’s stiffness and strength will decrease while its flexibility and elasticity will rise.

BioFila was created by twoBEars and is completely biodegradable, meaning it may be disposed of in landfills or soils. This substance is found in the cellular walls of plants and is made of lignin. It creates a unique filament that is tougher and more durable than PLA when combined with polymers. BioFila prints have a unique satin finish and are made in Germany. Depending on the print temperature, surface sheens can be modified. Silk is also available as an option for BioFila, which has the same properties as linen but is noted for its silky, glossy, liquid-like attributes.

We hope you have enjoyed our article covering some of the most common specialty 3D printing filaments and their great characteristics. If you are looking to purchase cutting-edge nylon carbon fiber filament for your next print, be sure to reach out to Filamatrix today!

There’s so much to learn about 3D printing materials. Come and find out what to look for when examining the different densities of 3D printing filaments.

Those interested in 3D printing have a lot to learn on how to use the system properly. Find out what you need to know about 3D printing and humidity levels.

3D printing has many variables that both beginners and experts need to know. Find out what effects temperature has on 3D printer filament.

Get professional insights, industry news, and our latest deals