A Look at the Different Densities of 3D Printing Materials

There’s so much to learn about 3D printing materials. Come and find out what to look for when examining the different densities of 3D printing filaments.

844-810-1385

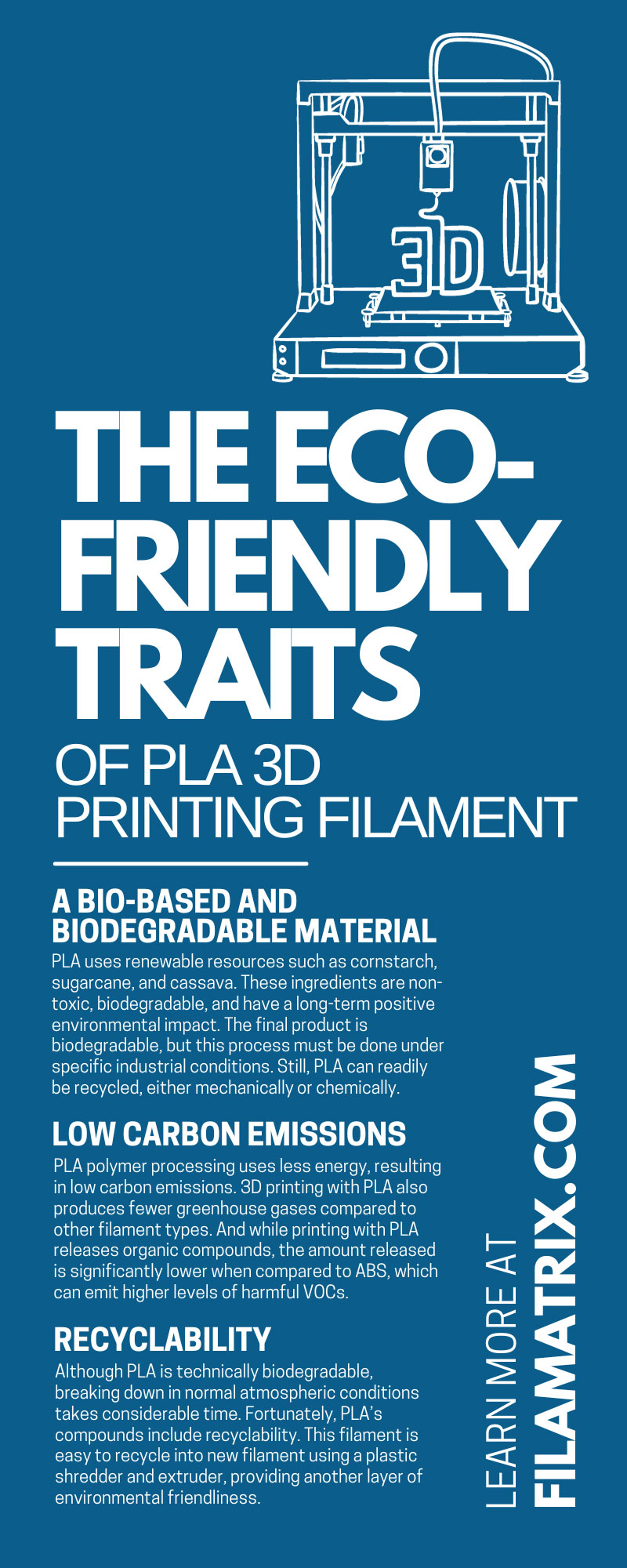

As global awareness about climate change and environmental issues grows, businesses seek more sustainable ways to reduce their carbon footprint. A prime area of sustainable practice is 3D printing; the adoption of this technology has led companies on a positive journey of embracing eco-friendly methods. A popular material among businesses investing in 3D printing is PLA, a biodegradable plastic with numerous other benefits. Learn more about the eco-friendly traits of PLA 3D printing filament so that you can see firsthand how this filament is helping shape a more sustainable world.

PLA, or Polylactic Acid, is unique in environmentally friendly 3D printing. This “biodegradable” filament derived from renewable resources such as corn starch or sugar cane offers an advantageous alternative to traditional, petroleum-based materials, such as ABS, PETG, and Nylon. PLA is also significant because it boasts a lower carbon footprint during production. When utilized in 3D printing, it allows businesses to minimize their environmental impact, aligning with the increasing demand for sustainability and responsible manufacturing practices. PLA doesn’t compromise on quality, offering durable, versatile, and high-resolution prints and proving that businesses can achieve both eco-friendliness and excellent results.

PLA uses renewable resources such as cornstarch, sugarcane, and cassava. These ingredients are non-toxic, biodegradable, and have a long-term positive environmental impact. The final product is biodegradable, but this process must be done under specific industrial conditions. Still, PLA can readily be recycled, either mechanically or chemically.

PLA polymer processing uses less energy, resulting in low carbon emissions. 3D printing with PLA also produces fewer greenhouse gases compared to other filament types. And while printing with PLA releases organic compounds, the amount released is significantly lower when compared to ABS, which can emit higher levels of harmful VOCs.

PLA is versatile in its range of applications, making it suitable for various industries, including medicine, electronics, and packaging. This material can be used to produce prototypes, packaging material, parts for medical implants, and toys. Its availability in various colors makes it easy to create eye-catching and vibrant designs that give products an edge in the market.

While PLA may not be as durable as, say, Nylon, it provides enough durability and stability for a wide range of applications. This makes it an excellent choice for printing sturdy, high-quality prototypes or models that require fine details. Additionally, PLA’s lower warping and shrinkage rates give it an edge in maintaining the desired shape and size during and after printing.

PLA is user-friendly, making it a popular choice among beginners. It has a lower printing temperature, which means all 3D printers can use it without needing a heated bed. Plus, PLA’s excellent adhesion to the printing bed reduces the chances of print failure, so printing with the filament is often smoother and more successful.

Although PLA is technically biodegradable, breaking down in normal atmospheric conditions takes considerable time. Fortunately, PLA’s compounds include recyclability. This filament is easy to recycle into new filament using a plastic shredder and extruder, providing another layer of environmental friendliness.

One of the intriguing properties of PLA is its translucence, which makes it an excellent choice for creating objects with aesthetic appeal. The diffuse dispersion of light through PLA enhances the visual quality of prints and allows for unique creations such as translucent vases, lamps, and decorative objects. Additionally, PLA 3D-printed objects are easy to sand and paint, providing extra customization options.

PLA’s mechanical properties are quite impressive. PLA has excellent tensile strength and moderate stiffness, making it suitable, reliable, and resilient for many applications. These properties, combined with its ease of printing, make PLA an excellent choice for both functional prototypes and end-use parts.

PLA works well with support structures that are necessary for printing complex designs. Its low warping factor ensures these structures are easy to remove without damaging the printed part. This allows the user to create intricate designs with overhangs and undercuts, broadening the scope of possible 3D-printed objects.

PLA has an excellent surface finish, meaning prints look smooth and professional straight from the printer. An excellent surface finish is a major advantage when creating detailed models or parts that require a high-quality finish. The superior surface quality of PLA prints also reduces the need for post-processing work, saving time and effort.

PLA has a low shrinkage rate during cooling, which reduces the risk of warping or deformation. The low shrinkage rate is useful when printing large objects with or without a high surface area. Even the smallest shrinkage can distort the final product, so using PLA for a low shrinkage rate can contribute to consistent results.

You can print at high speeds using PLA without compromising the final quality of your print. High-speed printing is a significant advantage in rapid prototyping or high-volume printing scenarios where time is critical. The swift printing capabilities of PLA make it a favorite choice among 3D printing enthusiasts and professionals alike.

One of the best eco-friendly traits of PLA filaments is its various available finishing techniques, such as sanding, gluing, and coating, allowing users to achieve desired aesthetics and functionalities efficiently. This characteristic makes PLA an excellent choice for those looking to customize their 3D prints beyond the printing process. Many cosplay performers use PLA to create ultra-realistic costumes and accessories.

PLA filament also comes in a wide array of colors and styles. PLA is easy to blend with materials such as wood and metal and is available in single and multi-color fibers.

Using PLA 3D printing filament is a significant win for businesses prioritizing sustainability. Its recyclable, non-toxic properties make it a popular choice for individuals and companies looking to reduce their carbon footprints. As the world continues to adopt eco-friendly materials, PLA 3D printing filament positions itself as the ideal material to incorporate into manufacturing processes. It’s cost-effective and versatile, and, most importantly, it contributes toward a safer, greener earth.

Get ready to embrace the future of 3D printing with Filamatrix. Our PLA plastic filaments lead the eco-friendly revolution, offering impressive functionality and sustainability in one package. Switch to the 3D side and join us on a filament-filled journey toward creating a greener, healthier world. Don’t just take our word for it; extrude the difference yourself.

Filamatrix

NEVER. FEEL. LIMITED.

There’s so much to learn about 3D printing materials. Come and find out what to look for when examining the different densities of 3D printing filaments.

Those interested in 3D printing have a lot to learn on how to use the system properly. Find out what you need to know about 3D printing and humidity levels.

3D printing has many variables that both beginners and experts need to know. Find out what effects temperature has on 3D printer filament.

Get professional insights, industry news, and our latest deals