A Look at the Different Densities of 3D Printing Materials

There’s so much to learn about 3D printing materials. Come and find out what to look for when examining the different densities of 3D printing filaments.

844-810-1385

Thermoplastic polyurethane (TPU) is perhaps the red-headed stepchild of 3D printing. It doesn’t fit the image of an industrial filament, like Nylon Carbon Fiber; you really don’t need flexible gears. And it isn’t really good for jewelry work. Rubber necklace anybody? So are there any advantages to printing with TPU filaments? Let’s find out.

TPU is “that flexible filament.” It’s floppy when you unspool it, rather like over-cooked spaghetti, but less sticky. You can stretch it a bit, and it recovers. And it can be difficult to feed into the hot end of some printers. But there are applications where it is cat’s pajamas. Here’s why.

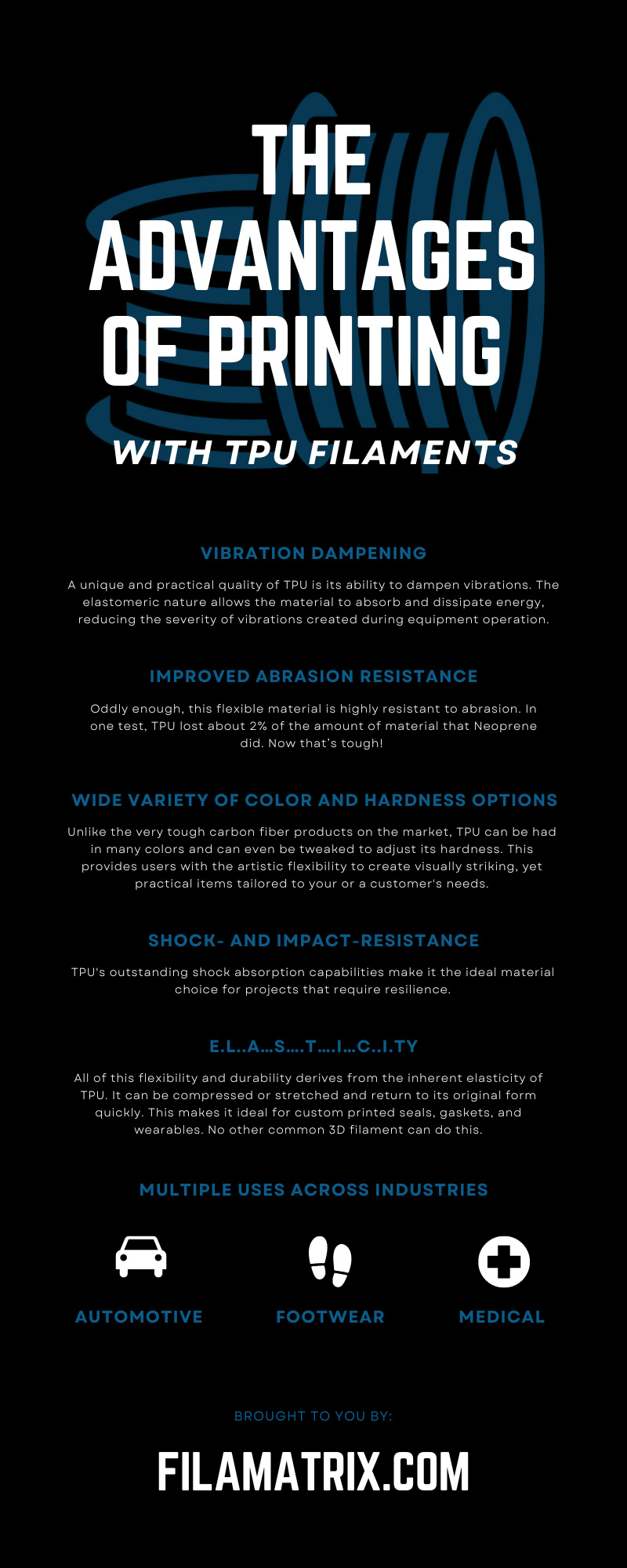

A unique and practical quality of TPU is its ability to dampen vibrations. The elastomeric nature allows the material to absorb and dissipate energy, reducing the severity of vibrations created during equipment operation. This can reduce wear and tear on attached equipment or isolate it from external forces. Think of 3D printed feet for your turntable so that three-year old running through the house doesn’t cause Paul Desmond’s Summertime to skip.

Oddly enough, this flexible material is highly resistant to abrasion. In one test, TPU lost about 2% of the amount of material that Neoprene did. Now that’s tough! So, if you use TPU for its vibrational absorption properties, it will last a long time too. Also consider it a buffer between machine parts that wear against one another.

Unlike the very tough carbon fiber products on the market, TPU can be had in many colors and can even be tweaked to adjust its hardness. This provides users with the artistic flexibility to create visually striking, yet practical items tailored to your or a customer’s needs. Shameless plug here, but do you know that Filamatrix can create custom colors to match your creative requirements? Not hit and miss, but computer-matched colors. Think about a flexible retail display for nail color in the color of the product.

TPU’s outstanding shock absorption capabilities make it the ideal material choice for projects that require resilience. Its inherent impact-resistance ensures that any 3D-printed items made with TPU handle the toughest environments you can literally throw at it. Maybe consider 3D printing your own shoes.

All of this flexibility and durability derives from the inherent elasticity of TPU. It can be compressed or stretched and return to its original form quickly. This makes it ideal for custom printed seals, gaskets, and wearables. No other common 3D filament can do this.

One of the standout benefits of TPU filaments is its wide range of applications across various industries. With its unique combination of flexible strength and elasticity, TPU withstands wear and tear and handles stress and pressure much better than other rigid materials like PLA or ABS. Here is a glimpse of the different industries using TPU filaments.

Automotive manufacturers are a major user of TPU due to its unique properties. TPU works well in printing lightweight, durable, and customizable car components such as seals, gaskets, and bushings. The inherent flexibility and strength of TPU make it an ideal material for manufacturing parts that endure significant wear and tear, ultimately contributing to improved performance and longevity of the final product.

TPU’s unique properties have also found multiple applications in the footwear industry. Due to its impressive flexibility and strength, shoe designers have used TPU filaments to create innovative designs that improve the midsole. TPU provides better cushioning, support, and durability, making it ideal for creating shoe soles which ensure excellent traction and comfort in various conditions.

The medical sector has also seen the benefits of using TPU. When producing parts for a medical facility, components must be flexible and resilient—medical tubing, biocompatible wristbands, and customized orthotic insoles. TPU’s sterilization capacity without compromising performance makes it the suitable filament choice for products that come into contact with patients.

The flexibility and elasticity of TPU filament make it an efficient and uniquely cost-effective prototyping choice. Designers and manufacturers save more time and money using lower-cost TPU filaments during the initial design stages. Utilizing TPU for prototype development allows for faster iteration cycles, reducing the cost of product development and time-to-market.

While transitioning from the prototyping phase to fit tests, one of the impressive things about TPU is that it doesn’t lose its strength, functionality, or durability. TPU prints resist pressure, wear, and harsh environments, so it’s the right choice for production design and functionality optimization. Creating complex shapes that bend, twist, and stretch into any desirable shape creates more independence in design and innovation during testing.

With its durability, flexibility, impact resistance, and vibration dampening, what’s not like about TPU? Perhaps the most unique filament in the pro printer’s toolbox, it can do what other filaments only dream of. Consider it for gaskets, shock absorbers, or even interface layers between more rigid materials that move against each other. Think outside the stupid box!

You can find six colors of TPU at Filamatrix. We’re filament manufacturers providing the best advice, tips, and tricks to finding a filament that matches your project’s needs. Browse our website for high-quality filaments and stay updated on tips and tricks with our blog.

There’s so much to learn about 3D printing materials. Come and find out what to look for when examining the different densities of 3D printing filaments.

Those interested in 3D printing have a lot to learn on how to use the system properly. Find out what you need to know about 3D printing and humidity levels.

3D printing has many variables that both beginners and experts need to know. Find out what effects temperature has on 3D printer filament.

Get professional insights, industry news, and our latest deals