A Look at the Different Densities of 3D Printing Materials

There’s so much to learn about 3D printing materials. Come and find out what to look for when examining the different densities of 3D printing filaments.

844-810-1385

The automotive industry is seeing some big changes, and it’s not just EVs making waves. Advancements in 3D printing are causing an upheaval in the way parts are made—both by manufacturers and aftermarket suppliers. From creating flexible parts to cutting down on processing times, here is how 3D printing is advancing the automotive industry.

The automotive industry was an early adopter of 3D printing, and for good reason. The ability to prototype parts rapidly and use these prototypes for testing dramatically reduced the concept to production time.

3D printing is also essential to the automotive industry because it enables customization on an unprecedented scale. Manufacturers have control over design modification before entering the final creation phase. One manufacturer is planning a flagship model with a dizzying array of options that will make every vehicle unique. This was last possible when coachmakers built cars from scratch in the early 20th century.

On top of this, existing vehicles can be customized with options that were unavailable when they were first built. And again, each customer can get a uniquely designed part. Functionality and art will breathe new life into older vehicles.

One of the most significant impacts of 3D printing is the creative freedom that it unleashes on automotive manufacturers. Traditional manufacturing methods are limited and may stifle the creation of new components. But 3D printing makes the manufacturing of lightweight, complex parts, such as lattice-structured components and organic designs, possible.

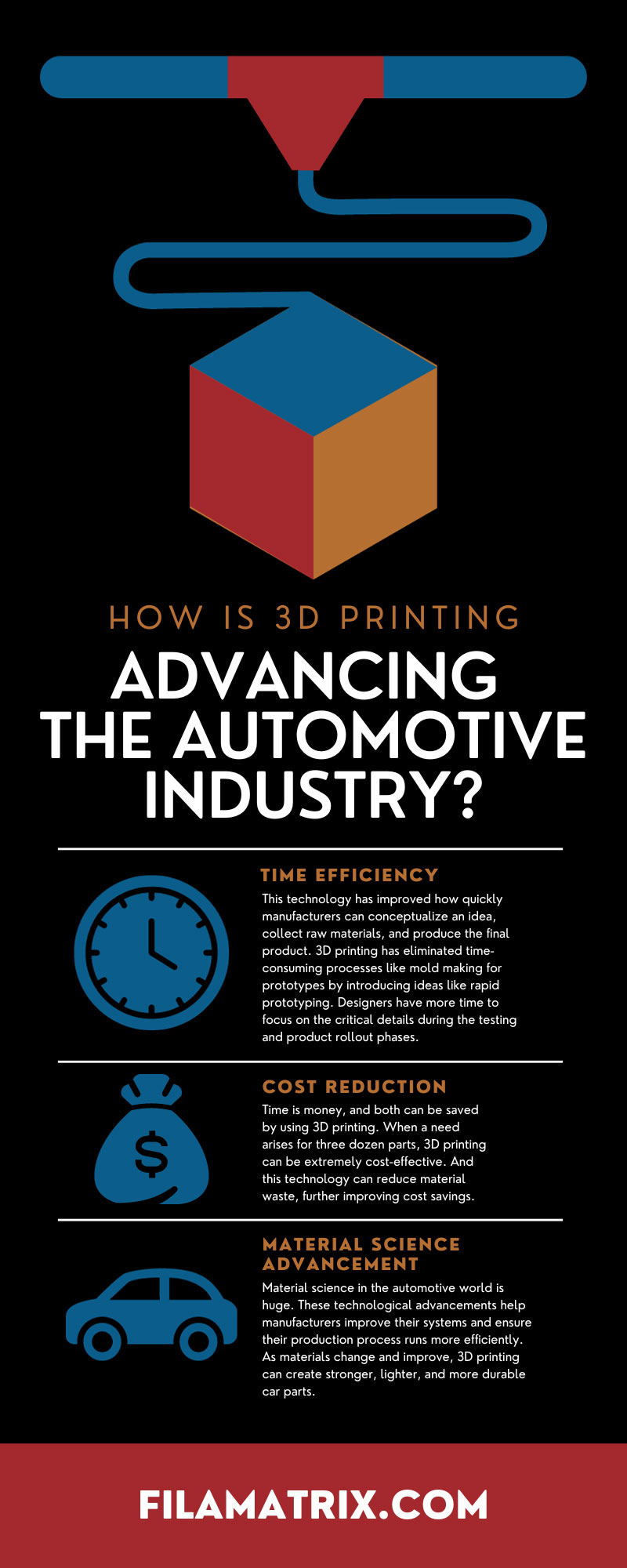

3D printing is the pinnacle of tech, and it’s only the beginning. We haven’t yet seen how much this process will transform the automotive industry. Here are some fantastic advantages of 3D printing in the automotive industry.

This technology has improved how quickly manufacturers can conceptualize an idea, collect raw materials, and produce the final product. 3D printing has eliminated time-consuming processes like mold making for prototypes by introducing ideas like rapid prototyping. Designers have more time to focus on the critical details during the testing and product rollout phases.

Time is money, and both can be saved by using 3D printing. When a need arises for three dozen parts, 3D printing can be extremely cost-effective. And this technology can reduce material waste, further improving cost savings.

Already, designers are working on 3D-printed crumple zones for new designs. This allows many different configurations to be tested with minimal changeover costs.

Material science in the automotive world is huge. These technological advancements help manufacturers improve their systems and ensure their production process runs more efficiently. As materials change and improve, 3D printing can create stronger, lighter, and more durable car parts.

Nothing in new technology is all roses and kittens. Here’s a brief look at the challenges and limitations that 3D printing faces in this industry.

As much as 3D printing can do things traditional manufacturing cannot, there are still ongoing issues of material limitations and costs. The more companies discover the capabilities of 3D printing, the more sophisticated the materials must become. This means better filaments, but you may spend a little more on specialized and advanced materials, and this limitation could offset the cost advantages of 3D printing.

Many of us have seen 3D-printed houses, but concrete is not a great material for the automotive industry. In most cases, build volumes are limited to a few cubic feet, so part sizes are likewise limited. Larger printers can be acquired, but such specialty items impact cost savings using 3D printing.

Unfortunately, you may find that integrating new and old methods isn’t as simple as you may expect. 3D printing could change your timeline, design terms, and material selections. While adapting to the times is essential, it isn’t always easy at first.

Always remember that 3D-printed parts can behave quite differently than similar parts made from traditional processes. So just because a part meets certain requirements imposed by a regulatory agency does not automatically mean the 3D-printed version will as well.

Where to begin on this one? If your staff makes parts and you are not using 3D printing in some capacity, it’s time to do some serious soul-searching. Get your staff up to speed. They don’t necessarily have to be experts, but they must be aware.

Sustainability is a hot topic, and 3D printing can help automotive manufacturers burnish their image in this area. This technology contributes to sustainable practices by using sustainable materials that are biodegradable, don’t emit carbon emissions while processing, and decrease carbon footprints.

But 3D printing can also reduce material waste. For small production runs, there is no need to spin up a casting or assembly line in some cases.

What can you imagine 3D printing doing in the automotive industry? It can probably do much more than you’d think. The technology has the potential to lead to replacement parts being printed by the local repair shop or even the vehicle owner. Why not print your vehicle at home and order a motor, battery, and controller?

So where to begin? Start by improving your manufacturing processes with 3D printing with a vast selection of filaments from Filamatrix. Automotive professionals in need of exceptional strength might consider our glass-reinforced nylon filament. Visit our site and learn about various types of 3D printer filaments on our blog.

There’s so much to learn about 3D printing materials. Come and find out what to look for when examining the different densities of 3D printing filaments.

Those interested in 3D printing have a lot to learn on how to use the system properly. Find out what you need to know about 3D printing and humidity levels.

3D printing has many variables that both beginners and experts need to know. Find out what effects temperature has on 3D printer filament.

Get professional insights, industry news, and our latest deals