A Look at the Different Densities of 3D Printing Materials

There’s so much to learn about 3D printing materials. Come and find out what to look for when examining the different densities of 3D printing filaments.

844-810-1385

In a world where plastic ducks are born from machines, there dwells a material so strong and versatile that even the bravest of blacksmiths would bow their heads in awe. This tale bestows the truth behind the modern urban legend of Nylon Kevlar filament.

In the labs of hardworking theorists, professionals study composites to create materials strong enough to craft practical, everyday items. Thus began the development of harder materials such as Nylon Kevlar, a heroic composite born from a union of gallant Nylon and resilient Kevlar. Use this guide for choosing the right Nylon Kevlar filament for your project to achieve what your projects need most: quality.

Nylon Kevlar filaments hold a unique position in 3D printing. This specific fiber melds the robustness and flexibility of Nylon with Kevlar’s high abrasion resistance, creating a unique performance and usability blend.

Nylon is a pretty impressive part of the Nylon Kevlar filament. On its own, it has magnificent strength and flexibility and shows superb layer adhesion, leading to prints with remarkable structural integrity. Conversely, its partner, Kevlar, has impressive abrasion resistance.

Overall, the blend of these two materials presents a fusion of durability, strength, and heat resistance. This extraordinary combination makes Nylon Kevlar preferred for a broad spectrum of 3D printing projects. These range from functional prototypes to end-use parts in diverse fields such as automotive, aerospace, or robotics.

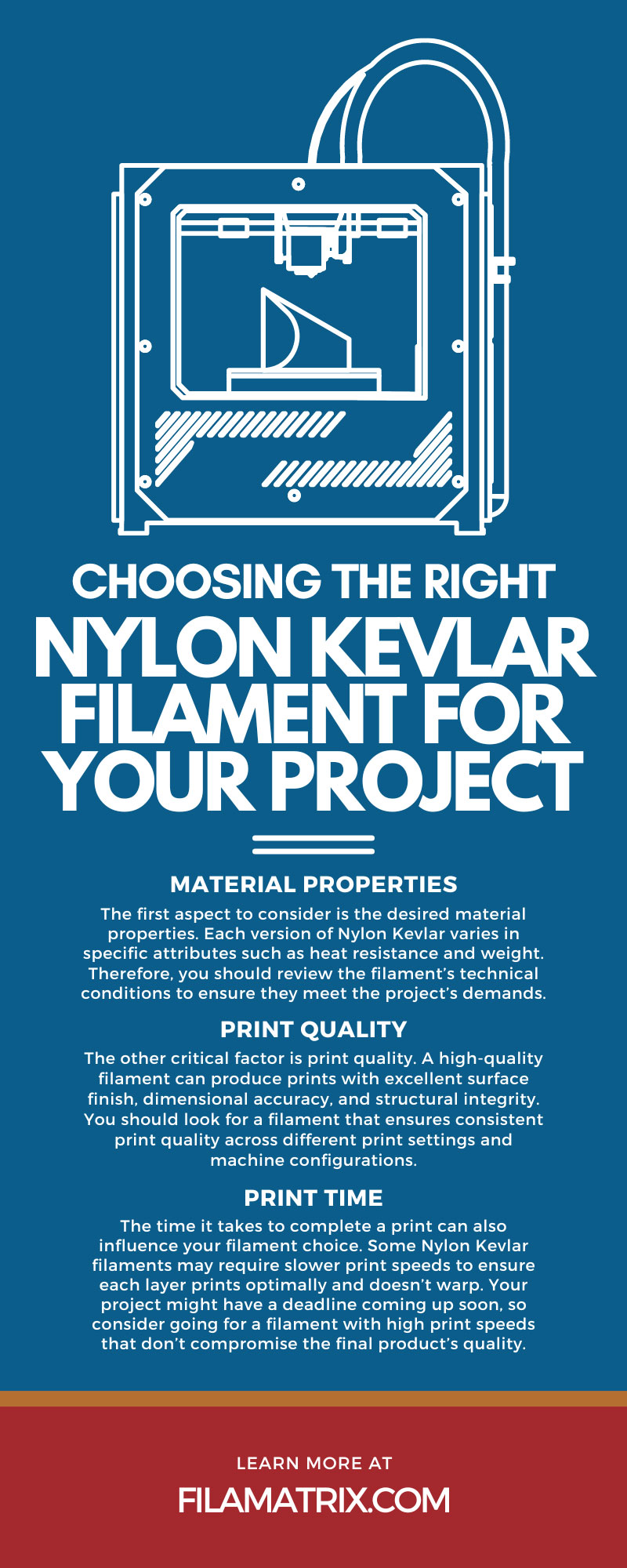

When selecting a Nylon Kevlar filament type for your 3D printing project, there are several factors to consider. However, the main thing to keep in mind is that the filament you choose needs to align with your specific project requirements.

The first aspect to consider is the desired material properties. Each version of Nylon Kevlar varies in specific attributes such as heat resistance and weight. Therefore, you should review the filament’s technical conditions to ensure they meet the project’s demands.

The other critical factor is print quality. A high-quality filament can produce prints with excellent surface finish, dimensional accuracy, and structural integrity. You should look for a filament that ensures consistent print quality across different print settings and machine configurations.

The time it takes to complete a print can also influence your filament choice. Some Nylon Kevlar filaments may require slower print speeds to ensure each layer prints optimally and doesn’t warp. Your project might have a deadline coming up soon, so consider going for a filament with high print speeds that don’t compromise the final product’s quality.

The application field is the final thing to factor in your filament choice. For instance, if you are in the aerospace industry working on a part, you might need a filament that offers exceptional strength and lightness. On the other hand, a filament with high heat resistance and durability might be more suitable for an automotive application.

These factors will help you choose the right Nylon Kevlar filament for your 3D printing project. Work to understand the material’s nuances and align it with your project requirements.

Nylon Kevlar filaments, renowned for their strength and versatility, find many applications in various industries. Consider some application examples to help you determine if a Nylon Kevlar filament is the right fit for your concept.

Nylon Kevlar is common in fields like automotive and aerospace. The reason it’s a popular choice is because of its best qualities, which are its high tensile strength, durability, and heat resistance. These benefits make it great for manufacturing parts that need to endure extreme conditions.

One of the most intriguing applications of Nylon Kevlar is in the military. The filament has led developers to create a combat robot named DDTV3. What makes this robot unique is its embedded fiber strands appearing in the print layers. The layer strands make it capable of withstanding significant impacts.

Fiber-reinforced Nylons have made 3D printing practical and affordable. These filaments can produce durable and rigid prints without a hefty price tag, making them accessible to more users.

Fabricated micro carbon fiber-filled Nylon reinforced with materials such as Kevlar and HSHT fiberglass has exceptional potential to push boundaries in advanced scientific research and development.

Nylon Kevlar filaments, known for their unparalleled strength and flexibility, can significantly change your 3D printing project. Explore some of the best practices that help you select filaments and maximize the benefits of this material.

When you are choosing a Nylon Kevlar filament, take a moment to scrutinize its specifications. Look for a filament that perfectly balances strength and flexibility for your unique project. Selecting a high-quality filament from a trusted manufacturer is critical—after all, you need to know that there will be no inconsistencies in the filament’s diameter that could affect the quality of your prints.

Nylon Kevlar is hygroscopic, meaning it directly absorbs moisture from the air, which can compromise your print quality and damage your printer. No matter how stringent or lenient the storage requirements may be, you should always store it in a dry and cool environment.

Not setting your printer to the right settings before printing with Nylon Kevlar can profoundly affect your project’s quality. Many Nylon Kevlar filaments require the extruder to be between 240 and 260 degrees Celsius and have a heated print bed to avoid warping. Try not to set the temperature too low, as low temperatures can produce poor layer adhesion. Meanwhile, too high of a temperature can burn the material.

Upon completion of the printing process, Nylon Kevlar usually requires post-processing to help achieve the outcome. Post-processing may include removing any support material or rafts and then sanding the print for a smoother finish.

By adhering to these best practices, you can ensure the Nylon Kevlar fiber you pick achieves the best results. Make sure you read your filament’s label before settling on a choice, as it can affect your printer’s settings, storage options, and post-processing techniques.

Nylon Kevlar filaments offer exceptional benefits for 3D printing projects with their strength, durability, heat resistance, and lightness. They can enhance various projects, from functional prototyping to end-use parts. As you make your choice, remember that when you decide to shop for Kevlar 3D printer filament with Filamatrix, you unleash a new world of limitless creativity and project potential. It’s time to print like you mean it!

Filamatrix

NEVER. FEEL. LIMITED.

There’s so much to learn about 3D printing materials. Come and find out what to look for when examining the different densities of 3D printing filaments.

Those interested in 3D printing have a lot to learn on how to use the system properly. Find out what you need to know about 3D printing and humidity levels.

3D printing has many variables that both beginners and experts need to know. Find out what effects temperature has on 3D printer filament.

Get professional insights, industry news, and our latest deals