When you’re building functional parts, prototypes, or production-grade components, heat resistance becomes a key factor. Whether working on automotive brackets, industrial jigs, or tooling for high-friction applications, your printed parts must withstand pressure and heat. That starts with using the right filament.

Not all 3D printing materials are suitable for extreme environments. Many degrade, soften, or lose their shape once exposed to elevated temperatures. That’s why it’s important to know which heat-resistant 3D printing material can handle the job. There are many options to choose from, including beginner-friendly PETG and ultra-durable PEEK. The material depends on your project’s thermal demands, your equipment, and the level of performance you need.

Let’s explore the best filaments for high-heat applications. Each material has its own strengths, printability traits, and use cases.

What Makes a Heat-Resistant 3D Printing Material

Before jumping into material choices, let’s define what makes a filament “heat resistant.” It comes down to a few key factors:

- Heat Deflection Temperature (HDT): The temperature at which a material begins to soften under a load. Higher HDTs mean better performance in hot environments.

- Melting Point: Some filaments can tolerate exposure to high ambient temperatures but still have relatively low melting points. Others remain solid and functional well beyond 200°C.

- Thermal Stability: Good heat-resistant materials should retain their mechanical properties intact during this process.

- Environmental Resilience: Some high-temp materials also resist chemicals, abrasion, or UV damage, which is a bonus for outdoor or industrial parts.

Proper heat-resistant 3D printing material should match your performance needs without adding unnecessary obstacles to your workflow. Now, let’s dig into the top contenders.

PETG: Reliable for Moderate Heat

PETG (Polyethylene Terephthalate Glycol) is the go-to filament when you need something more substantial than PLA but still easy to work with. It prints cleanly with minimal warping, doesn’t require an enclosure, and is more flexible than many rigid materials. Its HDT usually falls around 70–80°C, making it suited for moderately warm environments.

PETG performs well in both home and commercial printing setups. It’s a popular choice for items such as electronic housings, mechanical parts, and enclosures that may encounter high temperatures during use.

Why it works:

- Stable under moderate heat

- Excellent chemical and moisture resistance

- Doesn’t crack under stress like PLA

Things to consider:

- Not ideal for long-term exposure to very hot conditions

- Prone to stringing if print settings aren’t dialed in

A material that balances ease of use with solid thermal resistance is a smart pick for setups without enclosed printers or industrial-grade hardware. That’s where PETG stands out as a dependable choice.

ABS: Trusted for Toughness and Higher Temps

ABS (Acrylonitrile Butadiene Styrene) has earned its place in industrial 3D printing. With a heat deflection temperature of nearly 100°C, it outperforms PETG when exposed to higher temperatures. It’s also stronger and more impact-resistant, making it excellent for durable, load-bearing parts.

ABS is commonly used in automotive components, functional prototypes, and parts that require solid performance in high-temperature environments. It does require a heated bed and enclosed build space to reduce warping, but for serious makers, those are small trade-offs for big gains in performance.

Why it works:

- High thermal durability

- Good impact and wear resistance

- Widely available and affordable

Things to consider:

- Strong odors during printing; ventilation is key

- Susceptible to warping without temperature control

When printing parts exposed to engine heat or high-temperature machinery, you need a material that can handle the stress and stay durable. That’s why ABS is a reliable choice for these conditions.

PEEK: The Ultimate High-Heat Material

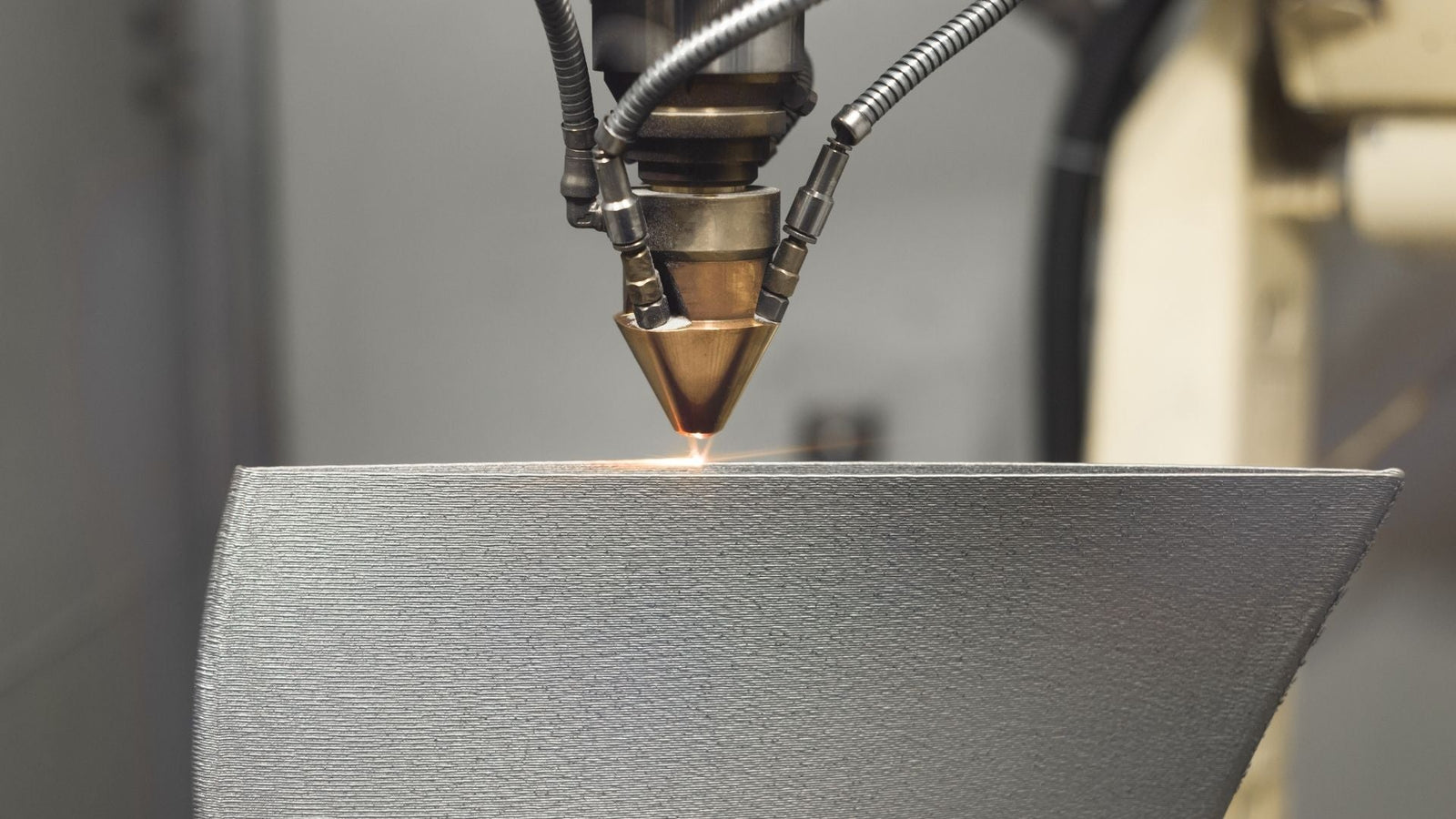

When performance is non-negotiable, PEEK (Polyether Ether Ketone) stands at the top of the materials list. This thermoplastic is commonly used in the aerospace, medical, and automotive industries due to its outstanding mechanical strength and heat tolerance. PEEK can withstand continuous use at temperatures over 250°C and peaks even higher without deformation.

This material isn’t for the average desktop printer. It requires an extrusion temperature of approximately 400°C, a heated build chamber, and careful control of drying before use. However, if your application involves friction, pressure, or intense thermal cycling, few materials come close.

Why it works:

- One of the highest performing thermoplastics available

- Stable under extreme thermal and mechanical stress

- Maintains properties in chemically aggressive environments

Things to consider:

- The cost is high compared to other filaments

- Requires industrial-grade hardware to print

- Needs to stay dry or performance drops fast

PEEK is the definition of a performance filament. If you’re manufacturing components for aerospace use, engine compartments, or medical-grade equipment, it’s worth the investment.

Nylon: Durable, Flexible, and Heat Tolerant

Nylon is one of the most versatile materials in the 3D printing world. It’s flexible, tough, and boasts a heat deflection temperature between 120 °C and 150°C, depending on the blend. Its flexibility helps absorb shock and resist wear, while its thermal stability makes it an excellent option for demanding mechanical parts.

Many overlook how well nylon handles heat. Its natural heat reflectivity allows parts to maintain shape even when repeatedly heated and cooled. This material’s characteristic supports functional items like gears, bushings, and brackets.

However, nylon is hygroscopic, meaning it pulls moisture from the air. That can cause print quality issues if the filament isn't stored correctly. Always keep nylon sealed with desiccant when not in use.

Why it works:

- Great for parts under mechanical and thermal stress

- Handles impact without breaking

- Resists warping with proper settings

Things to consider:

- Needs to be kept dry for optimal performance

- May need higher-end printers for best results

- Some variants require higher nozzle temps

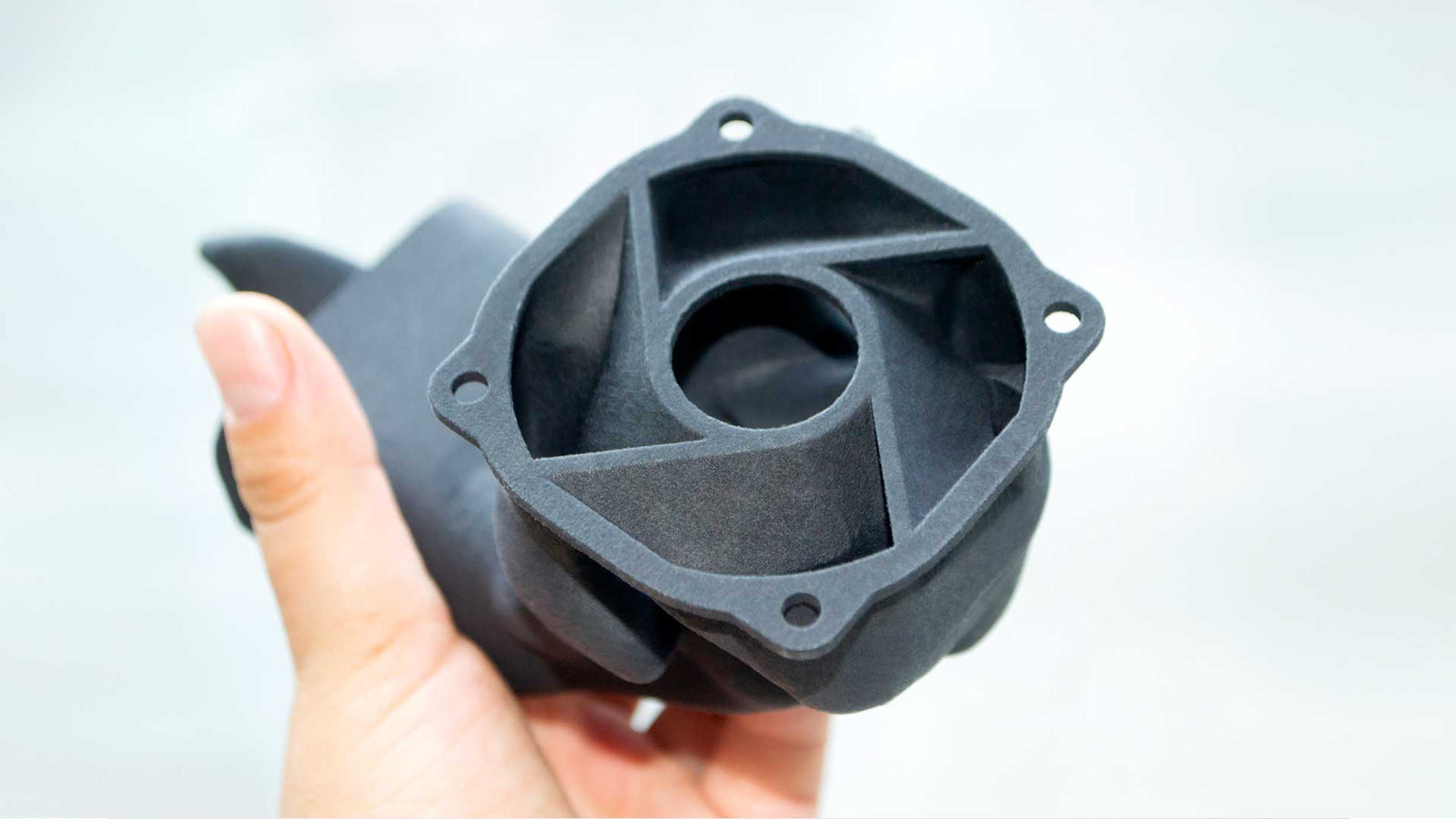

Specialty Nylon Blends: Reinforced for Extreme Conditions

At Filamatrix, we take it a step further by offering enhanced nylon blends specifically designed for heat resistance and durability. Our fiber reinforced Nylon line features options reinforced with carbon fiber, Kevlar, and glass fiber. Each option offers distinct benefits in terms of strength, stiffness, and wear resistance in high-temperature environments.

We design these blends to minimize warping and shrinking, even under prolonged exposure to high heat. Professional users rely on them for consistent dimensional accuracy and long-term strength in printed parts.

Here’s a quick breakdown of what each blend adds:

- Nylon + Carbon Fiber: Increased stiffness and strength with excellent dimensional stability

- Nylon + Kevlar: Boosted abrasion resistance with high flexibility

- Nylon + Glass Fiber: Better compressive strength for structural parts

With Nylon, you can build components that withstand real-world conditions.

Choosing the Right Material for the Job

No single filament can meet every demand. Your choice of heat-resistant 3D printing material depends on three core things:

- The environment you'll live in: How hot is it? Is there friction? Is it static or moving?

- Your printer’s capabilities: Not all materials are compatible with consumer-grade machines.

- The performance you need: Flexibility, stiffness, chemical resistance, or a blend?

PETG might be all you need for basic projects in warm environments. ABS takes things up a notch for more demanding tasks. Nylon covers most mechanical parts, providing flexibility with heat tolerance. PEEK is reserved for the most extreme conditions and delivers high performance when used correctly.

Heat-Ready Filaments Built to Last

Reliable materials start with precision manufacturing. Hence, every spool of filament we produce is made in the USA and tested with our exclusive 3-axis filament™ measurement system for consistent diameter and ovality. We maintain tight tolerances and work closely with customers across industries to provide filaments that meet real-world needs.

We offer:

- High-temp Phoenix Nylon filaments that resist warping and shrinking

- Specialty blends like Nylon Carbon Fiber, Glass Fiber, and Kevlar

- Classic and Tough PLA for lower-temperature projects

- PETG for dependable performance with less fuss

- Fast shipping on most orders and free shipping over $75

- Customization options

Are you printing one-off prototypes or scaling up production? We’re here with the materials and support to help you print with confidence. Explore our lineup of heat-resistant filaments and get the right material for your next high-temp project.

Frequently Asked Questions (FAQ)

What is the most heat-resistant 3D printing material?

The most heat-resistant 3D printing material is PEEK (Polyether Ether Ketone). It can withstand continuous use at temperatures exceeding 250°C and tolerate peaks well beyond 300°C. It maintains structural integrity under extreme thermal and mechanical loads, which is why it’s used in aerospace, automotive, and medical industries. However, it requires a high-performance printer capable of extruding at around 400°C and an enclosed chamber.

Can I print heat-resistant materials on a standard desktop 3D printer?

Yes and no. Upgraded desktop printers with heated beds and basic temperature control can print materials such as PETG and ABS. PETG is especially beginner-friendly and doesn’t require an enclosure. ABS may need an enclosed chamber to avoid warping. More advanced materials often require specialized hardware, including high-temperature nozzles and heated enclosures.

Is Nylon a good material for high-temperature applications?

Yes, Nylon is one of the best options for applications that require both durability and thermal stability. Depending on the blend, Nylon can withstand temperatures between 120°C and 150°C. Specialty Nylon reinforced with carbon fiber, Kevlar, or glass fiber can further improve heat resistance and mechanical properties.

How do I store heat-resistant filaments like Nylon or PEEK?

Nylon and PEEK are both hygroscopic, meaning they absorb water from the air. If stored improperly, this moisture can cause poor surface finish, bubbles, or even compromised strength in your prints. Always keep these filaments sealed in airtight containers with desiccant packs to prevent moisture damage. Using a filament dryer before printing can also help.

Are heat-resistant materials more difficult to print?

Some are. PETG is relatively easy to print and represents a significant improvement over PLA. ABS and Nylon require more precise settings and environmental control, while PEEK demands industrial-grade equipment. Print difficulty increases with performance, so it’s important to match your material choice with your printer’s capabilities and your experience level.

What can I print with heat-resistant 3D materials?

These materials are commonly used to print automotive parts, brackets, functional prototypes, mechanical components, fixtures, and enclosures. Anywhere heat, friction, or mechanical stress is present, a heat-resistant filament helps produce a part that holds up over time.

Can I use heat-resistant filaments for outdoor applications?

Yes, many heat-resistant filaments also offer excellent weather resistance. For instance, ABS and nylon perform well in outdoor environments if appropriately treated. However, UV resistance varies depending on the material.

PETG exhibits decent UV resistance, whereas ABS may degrade over time without the application of additional protective coatings. Nylon reinforced with carbon or glass fiber generally handles outdoor conditions well, especially in high-heat settings.