Carbon fiber filaments are having a moment, and for good reason. With reliable strength, low weight, and excellent durability, they’re showing up everywhere from jet engines to hockey rinks. Materials like Nylon CF, PET CF, and PLA CF are quickly becoming favorites across industries that need reliable, high-performance parts without the bulk.

At Filamatrix, we’ve seen firsthand how businesses are pushing limits with carbon fiber filaments. If you're designing aerospace components, medical tools, or drone parts, the benefits are hard to ignore. So if you're asking what industries should consider carbon fiber filaments, the short answer is: probably yours.

Yet, let’s not stop at the short answer. Let’s take a closer look at what carbon fiber is used for and why more industries are choosing these advanced materials to lead the way.

What Is Carbon Fiber Used For?

Carbon fiber has long been recognized for its strength-to-weight ratio. However, that’s just the start. When carbon fibers are blended into thermoplastics like PLA, PETG, or Nylon, they create filaments that deliver higher stiffness, lower thermal expansion, and greater impact resistance. These are practical advantages that make carbon fiber-reinforced filaments a strong alternative to metals or unfilled plastics.

Here’s how carbon fiber filaments stand out:

- Lightweight strength: They reduce weight while keeping critical strength where it matters.

- Enhanced thermal resistance: Ideal for applications that operate in high-temperature environments.

- Dimensional stability: Less warping and shrinkage during and after printing.

- Surface quality: Components come out with a matte, professional finish—no post-processing required.

So, what is carbon fiber used for? Everything from structural brackets in airplanes to orthopedic tools in hospitals.

Let’s have a look at some of the top sectors.

Aerospace

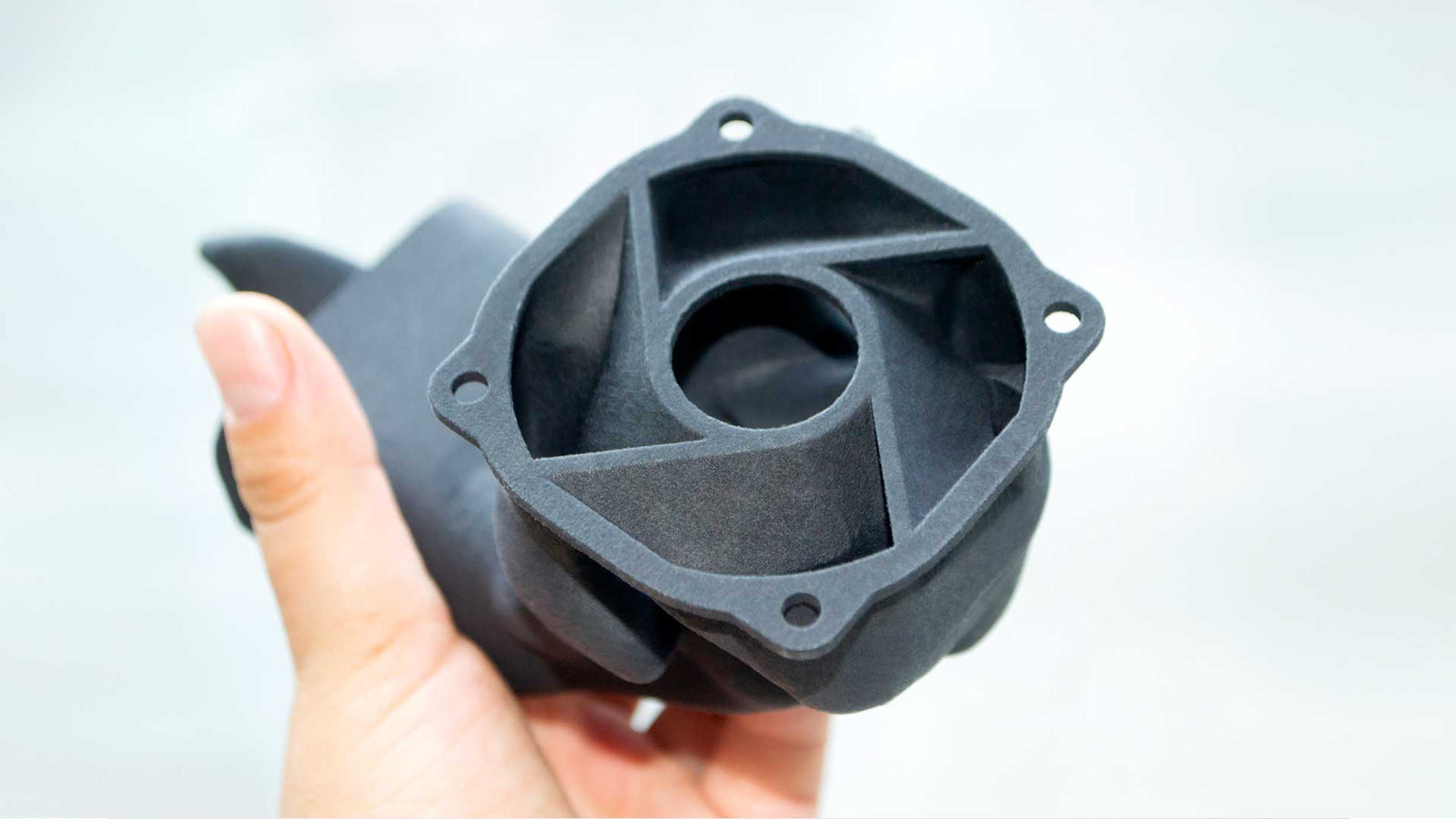

The aerospace industry requires lightweight materials. Every extra pound on an aircraft affects fuel use, performance, and emissions. That’s why carbon fiber filaments are such a great complement to this industry. Components like ducting, housings, clips, and even customized jigs and fixtures can now be printed with Nylon CF or PET CF for dependable strength without added mass.

In aerospace, tolerances matter. That’s why carbon fiber filaments are used in both prototyping and production. They hold their shape under pressure and temperature fluctuations. These features make them a dependable part of the workflow from concept to airworthy parts.

The result? Lighter aircraft, lower operating costs, and better environmental performance. If you’re working in aerospace and not using carbon fiber filaments yet, you’re probably already falling behind.

Automotive

From factory floors to custom garages, the automotive world has embraced carbon fiber filaments with open arms. These materials help manufacturers reduce vehicle weight while boosting speed, safety, and fuel economy. You’ll find carbon fiber-reinforced parts in everything from under-the-hood brackets to custom dashboards.

Engineers working on electric vehicles especially benefit from these materials. Lowering the weight of the vehicle frame means batteries go farther. When you're trying to squeeze every mile out of a charge, every ounce matters.

The aftermarket world is also jumping on board. Hobbyists and modders are printing Nylon CF intake manifolds, supports, and interior upgrades with parts that look sharp and last long. Carbon fiber has become the new standard for performance builds, custom projects, and repair parts that last.

Renewable Energy

In the renewable energy sector, reliability is the name of the game. Wind turbines and solar panels operate under harsh conditions: extreme heat, cold, wind, salt, and moisture. Carbon fiber filaments offer durability and strength that traditional plastics just can’t match.

Turbine blade components, sensor housings, and structural supports made from PET CF or Nylon CF last longer and perform better in the field. They resist corrosion, tolerate UV exposure, and stay rigid over time, which helps keep operations running longer between maintenance intervals.

Solar systems use carbon fiber in racking systems and panel mounts to reduce weight. These components stay stable while supporting panels in demanding environments. With energy costs and efficiency under constant scrutiny, small gains from lighter and stronger parts add up fast.

The transition to greener energy doesn’t happen with guesswork. It happens with smarter materials; carbon fiber filaments are helping make that change a lot more practical.

Medical

Precision and cleanliness are non-negotiable standards in the medical manufacturing industry. Carbon fiber filaments offer excellent rigidity, are biocompatible, and don’t interfere with imaging technologies like X-rays or MRIs. That makes them perfect for external supports, surgical tools, and diagnostic fixtures.

Nylon CF is frequently used for patient-specific guides and jigs, which surgeons rely on for accuracy. These parts must maintain tight tolerances while remaining lightweight and comfortable. Since carbon fiber filaments are non-toxic and hypoallergenic, they’re suitable for sensitive environments.

In lab and testing environments, carbon-reinforced components also improve reliability. They’re chemically resistant and maintain structural integrity over repeated sterilizations.

Sports and Recreation

In competitive sports, shaving off weight without losing strength is a constant goal. Carbon fiber filaments enable manufacturers to create lighter, stronger gear without compromising performance or comfort. Tennis rackets, cycling components, skis, surfboards, hockey sticks; you name it, and carbon fiber is already in it.

Yet, what sets filament-based carbon fiber gear apart is customization. 3D printing with carbon fiber lets sports brands and innovators fine-tune designs to exact dimensions, balance points, and ergonomic preferences. That kind of customization just wasn’t practical before.

From racing bikes to custom cleats, athletes can now get gear dialed in exactly the way they want. Manufacturers can test, revise, and refine designs in real time. They can do so all without wasting resources on slow, traditional fabrication.

Robotics and Automation

Carbon fiber filaments are showing up on factory floors in ways you might not expect. Robotic arms, grippers, end effectors, and machine housings all benefit from parts that are lightweight, durable, and dimensionally stable.

In high-speed manufacturing environments, every millisecond counts. Lighter robotic components move faster with less wear, resulting in longer uptime and lower maintenance costs. PET CF and Nylon CF both offer the kind of impact resistance and stiffness that robotic systems need to stay accurate and reliable.

Carbon fiber filaments are also perfect for jigs and fixtures used in automation. These parts often take a beating during regular use. Reinforced filament helps them withstand repeated wear without adding extra bulk.

Consumer Electronics and Drones

Drones, wearables, and portable electronics are all about performance in small, lightweight packages. That’s why carbon fiber filaments are becoming a go-to material for enclosures, brackets, and frames in the consumer tech space.

Drones especially benefit. Lighter frames result in longer flight times and improved agility. Filament-based carbon fiber also helps reduce vibration, which enhances camera stabilization and sensor performance.

PLA CF is often the first choice for prototyping new devices or custom accessories. It prints cleanly, holds detail well, and provides designers with a quick way to test real-world functionality without moving to full-scale injection molding.

So, What Is Carbon Fiber Used For? Just About Everything

Carbon fiber filaments have become a frontline material used by some of the most demanding industries worldwide. Aerospace teams rely on them to reduce the weight of aircraft. Automotive engineers use them to drive efficiency. Medical manufacturers count on them for precision tools. And designers across consumer tech, sports, and energy use them to push new boundaries.

So, what is carbon fiber used for? It’s used to build smarter, lighter, tougher, and more reliable products at a faster rate.

At Filamatrix, we’re proud to be part of that evolution. We manufacture all our carbon fiber filaments right here in the USA, utilizing 3-axis measurement technology for excellent tolerance control. Our lineup includes:

- Nylon CF Hydrophobic: takes the improvements of our Nylon Hydrophobic filament with regards to moisture, and improves the physical properties with the added benefit of carbon fiber reinforcement

- PET Carbon Fiber Filament: Stiff and impact-resistant with excellent dimensional stability.

Need customization? We offer custom solutions with low minimums, fast turnaround times, and a technical team ready to help you select the suitable filament for your exact needs.

Frequently Asked Questions About Carbon Fiber Filaments

What is carbon fiber used for in 3D printing?

In 3D printing, carbon fiber is used to reinforce base filaments, such as PLA, PETG, and Nylon. The result is a material that’s stiffer, stronger, and more heat-resistant than standard thermoplastics. You’ll commonly find carbon fiber filaments used for brackets, housings, jigs, fixtures, and structural components.

What’s the difference between PLA CF, PET CF, and Nylon CF?

All three materials are infused with carbon fiber but differ in their base plastic:

- PLA CF: Easiest to print with, great for prototypes or non-load-bearing parts. It prints with excellent detail and produces a nice matte finish, but it is more brittle.

- PET CF: Offers a balance between ease of use and performance. It has better impact resistance than PLA and is suitable for moderate mechanical parts.

- Nylon CF: The most durable and flexible of the three. It's tough, chemical-resistant, and ideal for load-bearing or high-stress applications; however, it requires higher temperatures and more precise print conditions.

Each type serves different needs, so the best one depends on your application.

Do carbon fiber filaments damage 3D printer nozzles?

Yes, carbon fiber filaments are abrasive. Over time, they will wear down standard brass nozzles. To prevent damage and maintain print quality, we recommend using a hardened steel, ruby-tipped, or nozzleX type nozzle when printing with any carbon fiber-filled material. It's a simple upgrade that protects your equipment.

Are carbon fiber 3D printed parts stronger than metal?

It depends. While carbon fiber filaments can’t fully match the tensile strength of metals like steel or aluminum, they offer excellent strength-to-weight ratios, often outperforming metals in applications where weight matters more than absolute strength. A carbon fiber-reinforced plastic part can offer the ideal combination of stiffness, weight, and cost-effectiveness.

Is carbon fiber filament conductive?

Carbon fiber itself is conductive, however when mixed into a plastic matrix that provides insulation it is significantly reduced. Conductivity ranges of carbon fiber filaments are typically categorized more as static dissipative.

How should I store carbon fiber filament?

Carbon fiber filaments, especially those with Nylon or PETG bases, are hygroscopic, meaning they absorb moisture from the air. Moisture can cause poor layer adhesion, surface defects, and weak prints. Store your filament in a sealed bag with desiccant or use a dry box to maintain optimal condition.

Can I use carbon fiber filaments in any 3D printer?

Not all printers are ready for carbon fiber filaments out of the box. You’ll need a printer with:

- A heated bed

- A hardened nozzle

- An all-metal hot end (especially for Nylon CF)

- An enclosure (recommended for Nylon CF to prevent warping)

If your printer meets these specs, you’re ready to start printing high-performance parts with carbon fiber-reinforced materials.

Do carbon fiber parts look different after printing?

Yes, and in a good way. Carbon fiber filaments produce a clean, matte finish that hides layer lines and gives parts a professional look straight off the bed. It’s a favorite among manufacturers and designers who need their parts to look good and perform even better.