A Look at the Different Densities of 3D Printing Materials

There’s so much to learn about 3D printing materials. Come and find out what to look for when examining the different densities of 3D printing filaments.

844-810-1385

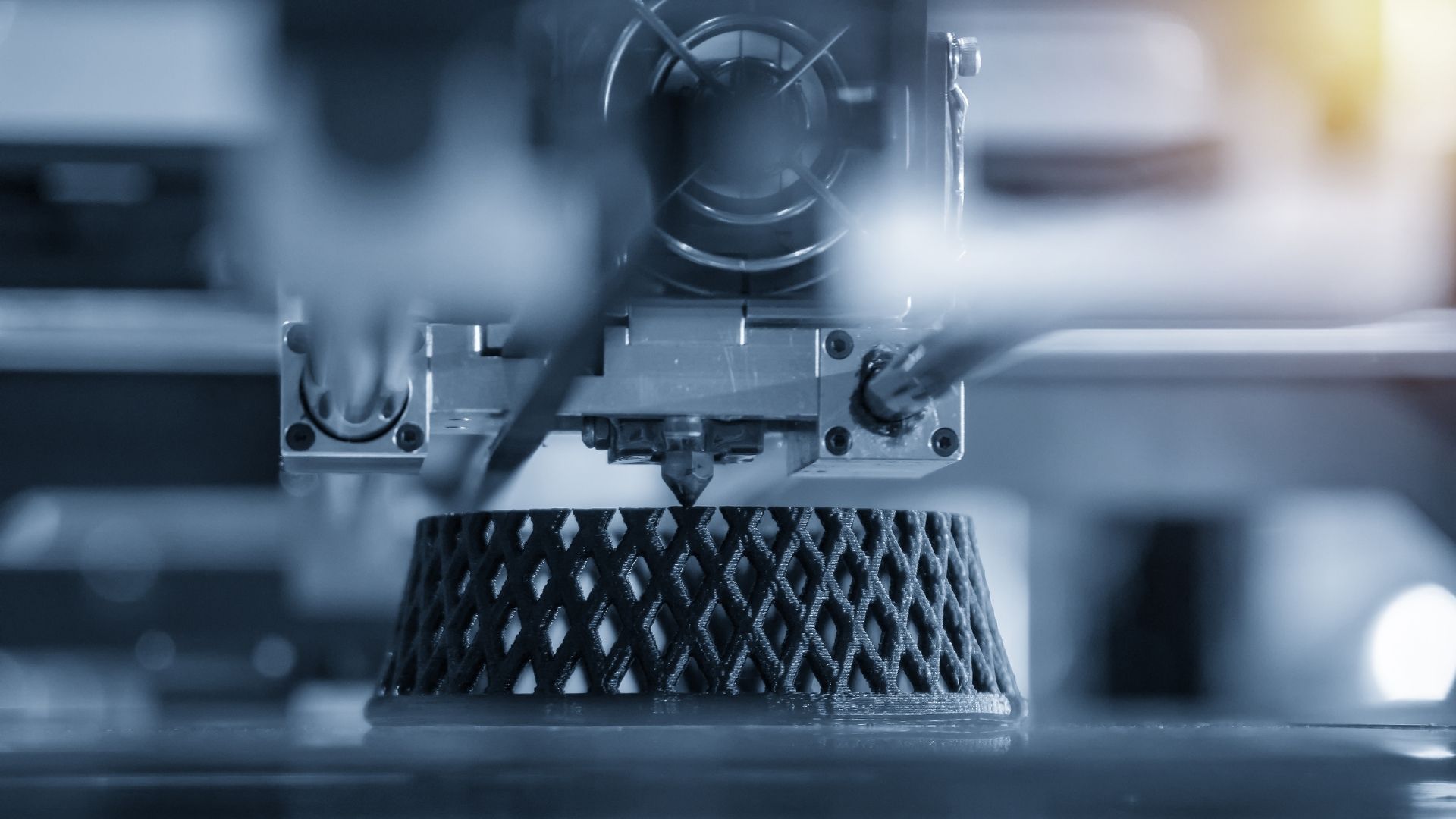

The use of nylon filaments during the 3D printing process has skyrocketed in popularity over recent years. This material gives a product strength and durability, and it also provides a diversity that’s unrivaled by any of the other options out there. As such, it’s a resource you might want to consider using yourself. But printing with nylon comes with a few unique factors to consider, and it’s important that you know these features to get the most out of the process. This is what you need to know about nylon 3D printing.

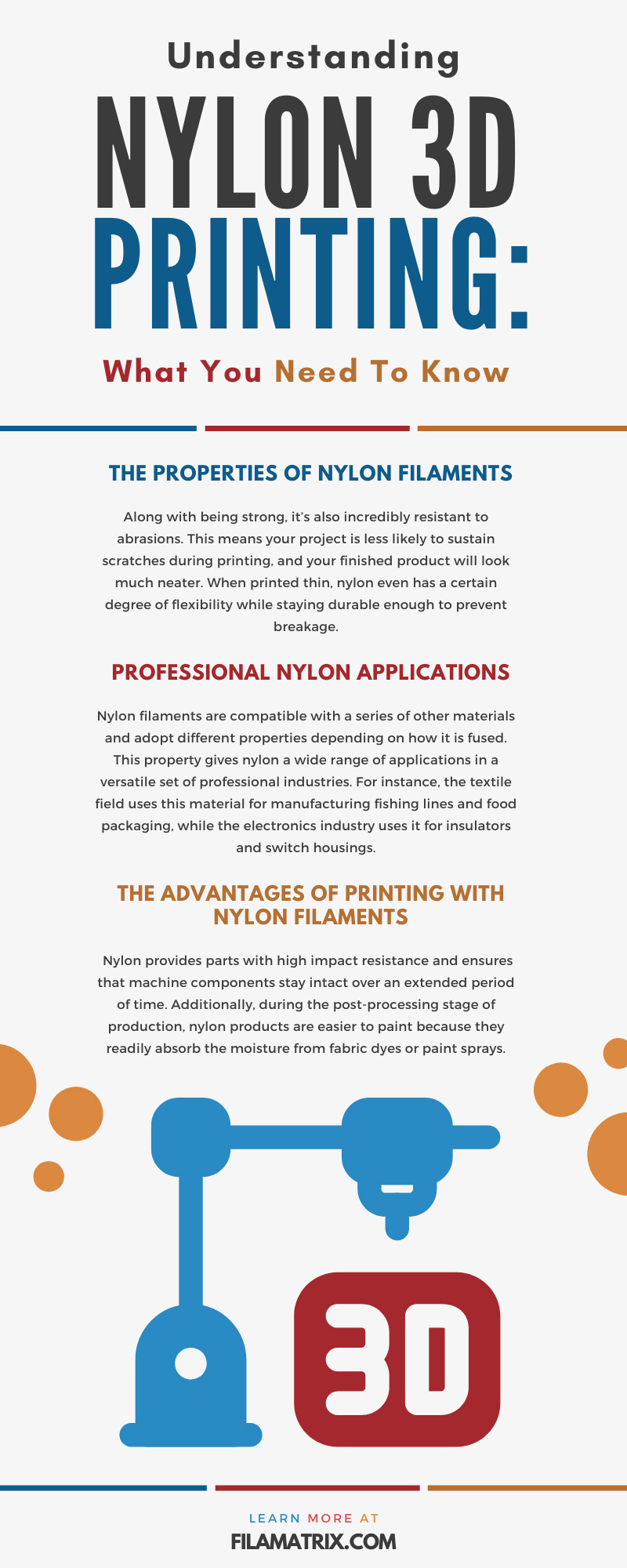

To produce quality products with nylon filament, you first need to understand the unique characteristics it brings to the table. Along with being strong, it’s also incredibly resistant to abrasions. This means your project is less likely to sustain scratches during printing, and your finished product will look much neater. When printed thin, nylon even has a certain degree of flexibility while staying durable enough to prevent breakage. Nylon, being a slicker material, has a low coefficient of friction, too—which increases its functionality in the form of equipment prototypes.

Nylon has a series of chemical properties to consider as well, such as its high melting point and hygroscopic nature. The high melting point makes it soft enough to fuse with a multitude of other substances. Nylon usually combines with materials like glass and carbon fiber to give it secondary effects, like lower flexibility, higher flexural strength, and stiffer parts. Being hygroscopic, however, makes it particularly susceptible to water. In fact, absorbing water from the air can affect the stability of your printed result.

As previously mentioned, nylon filaments are compatible with a series of other materials and adopt different properties depending on how it is fused. This property gives nylon a wide range of applications in a versatile set of professional industries. For instance, the textile field uses this material for manufacturing fishing lines and food packaging, while the electronics industry uses it for insulators and switch housings. Even pieces of manufacturing machinery, such as gears and rollers, consist of low-friction nylon to improve equipment efficiency.

Naturally, this versatility means that there are several advantages to working with nylon over other filament materials. For starters, nylon provides parts with high impact resistance and ensures that machine components stay intact over an extended period of time. Additionally, during the post-processing stage of production, nylon products are easier to paint because they readily absorb the moisture from fabric dyes or paint sprays. In general, nylon filaments are a wonderful all-around material for functional and attractive projects—no matter what you’re planning to make.

The most important thing to know about nylon 3D printing though, is how to get the results you’re after. It’s only through a quality printing process that your nylon filaments can utilize all their best traits in your design. Here are a few tips to maximize your rate of success.

As mentioned, nylon has a very high melting point compared to other 3D filaments. At 240 degrees or above on average, you need a printer that can handle these temperatures. Otherwise, you risk your system breaking down in the process. Prior to starting your printing project, make sure that you check the maximum temperature on your FDM printer extruder. This way, you know right away whether nylon is a good option for your project.

It’s also important that you have the means to properly store your nylon filaments between uses. Since nylon will absorb any moisture in the air, keeping it exposed slowly reduces its integrity while the printer isn’t running. The longer these materials sit out, the higher your chances of creating a low-quality print. Because of this, you should preserve these filaments by removing their spools from the printer and packing them in an airtight container until you need them next. Fortunately, certain specialized products allow you to feed the nylon strands into the printer while keeping them mostly protected from the open air. Keep a lookout for these containers to make preserving your nylon filaments easier and more efficient.

Another helpful practice to keep in mind is to use a printer with a heated chamber when working with nylon. It’s important to note that some variations of nylon filament can warp due to the extreme temperature changes between the plastic and the environment around it. It’s often effective to use a printer with a built-in heat enclosure. These components keep the heated parts of your printer at a consistent temperature while melting the nylon. This decreases the risk of the material coming into contact with the outside air and thus minimizes the potential for warping.

Above all though, you should make sure that you’re printing your product in a dry environment. Moisture is the leading cause of deterioration during nylon printing projects. It can even result in your model falling apart after production. The less interaction these materials have with a humid space, the better your results will be. Choose an area of your business that’s far away from any exterior doors or windows, and do your best to control the number of people moving in and out of that space at a given time. If you’re still concerned about humidity in your business, you can install a dehumidifier to help remove water from the air near your 3D printer.

Filamatrix supplies hundreds of different industries with premium nylon carbon fiber filament. Our materials provide all the durability you’d count on from nylon, with the heat deflection and diameter benefits of the carbon fiber reinforcement. Developed by experienced engineers, we’re confident in the filament’s ability to maintain color uniformity as well as hold up against any manner of stressor. For more information about our large array of printing filaments, reach out to us today.

There’s so much to learn about 3D printing materials. Come and find out what to look for when examining the different densities of 3D printing filaments.

Those interested in 3D printing have a lot to learn on how to use the system properly. Find out what you need to know about 3D printing and humidity levels.

3D printing has many variables that both beginners and experts need to know. Find out what effects temperature has on 3D printer filament.

Get professional insights, industry news, and our latest deals