A Look at the Different Densities of 3D Printing Materials

There’s so much to learn about 3D printing materials. Come and find out what to look for when examining the different densities of 3D printing filaments.

844-810-1385

PETG is a strong, temperature-resistant, and highly impact-resistant plastic commonly used in FDM-style 3D printing. This content contains a lot of information; for more, see our guide to the optimal PETG settings.

Here, we’ll walk you through how to print using PETG and how to fix typical problems. While printing with PETG is less difficult than printing with ABS, it does have its own set of challenges, which we’ll discuss below. Even yet, with a little effort, PETG filament may produce exceptionally strong and high-quality prints. Here are our top tips for how to properly 3D print when working with PETF filament.

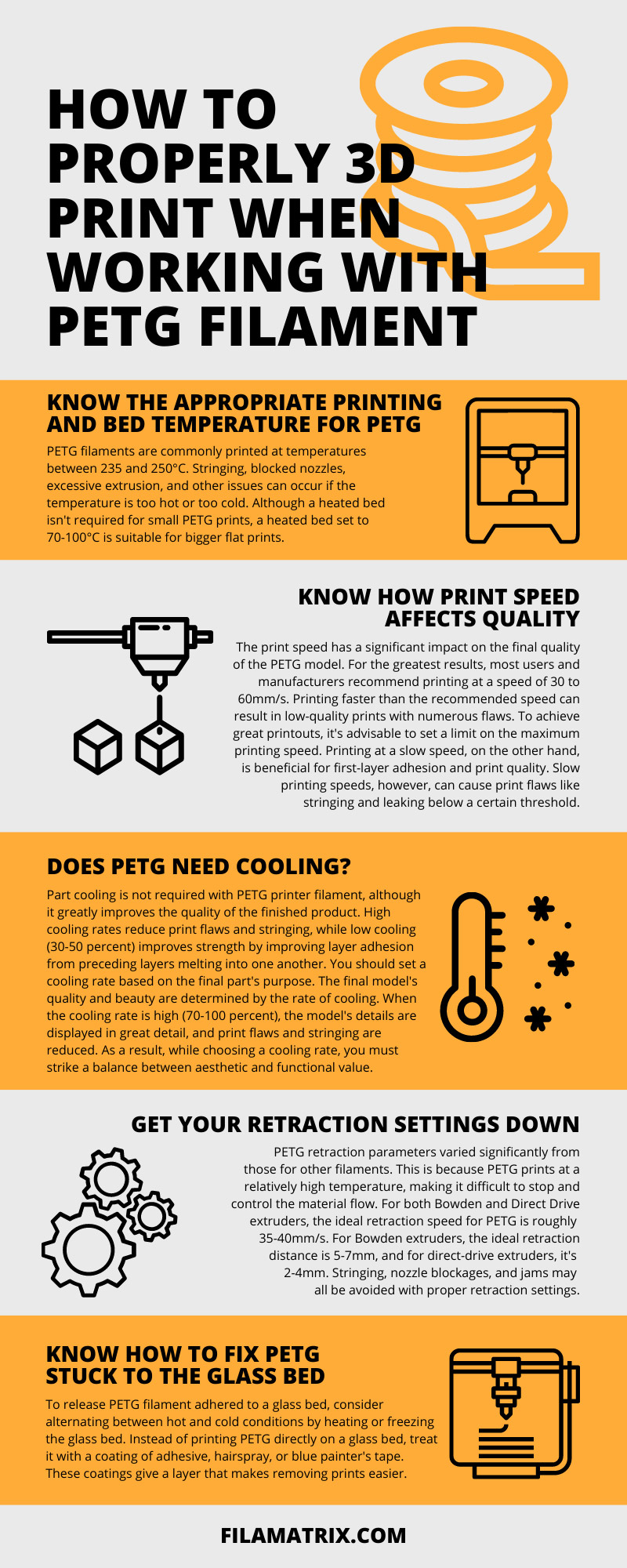

PETG filaments are commonly printed at temperatures between 235 and 250°C. Stringing, blocked nozzles, excessive extrusion, and other issues can occur if the temperature is too hot or too cold. Although a heated bed isn’t required for small PETG prints, a heated bed set to 70-100°C is suitable for bigger flat prints.

For different types of filaments, print temperatures can vary within the limits listed above. Use the temperature numbers provided by the filament makers for the best results, and modify the settings if necessary. You can also use old-fashioned trial and error to figure out what temperature is best for your filament. The temperature tower and other calibration prints can assist in determining the optimum filament parameters.

The print speed has a significant impact on the final quality of the PETG model. For the greatest results, most users and manufacturers recommend printing at a speed of 30 to 60mm/s. Printing faster than the recommended speed can result in low-quality prints with numerous flaws. To achieve great printouts, it’s advisable to set a limit on the maximum printing speed. Printing at a slow speed, on the other hand, is beneficial for first-layer adhesion and print quality. Slow printing speeds, however, can cause print flaws like stringing and leaking below a certain threshold. Finally, keep in mind that the best printing speed varies between printers and filament brands. You should probably experiment with the parameters to find the sweet spot for the best results. The sort of model being printed should also influence the printing speed. A slower printing speed is likely to be beneficial for models with curved or complex geometry.

Part cooling is not required with PETG printer filament, although it greatly improves the quality of the finished product. High cooling rates reduce print flaws and stringing, while low cooling (30-50 percent) improves strength by improving layer adhesion from preceding layers melting into one another. You should set a cooling rate based on the final part’s purpose. The final model’s quality and beauty are determined by the rate of cooling. When the cooling rate is high (70-100 percent), the model’s details are displayed in great detail, and print flaws and stringing are reduced. As a result, while choosing a cooling rate, you must strike a balance between aesthetic and functional value.

PETG retraction parameters varied significantly from those for other filaments. This is because PETG prints at a relatively high temperature, making it difficult to stop and control the material flow. For both Bowden and Direct Drive extruders, the ideal retraction speed for PETG is roughly 35-40mm/s. For Bowden extruders, the ideal retraction distance is 5-7mm, and for direct-drive extruders, it’s 2-4mm. Stringing, nozzle blockages, and jams may all be avoided with proper retraction settings.

PETG offers reasonable heat resistance, especially when compared to most other filaments. It can withstand temperatures up to its glass transition temperature, which is between 80 and 85 degrees Celsius. It easily outperforms PLA filaments in this regard, but it is less heat resistant than ABS. It is, however, more UV resistant than both, making it an excellent choice for outdoor use.

When printing PETG, a number of difficulties might lead to poor first layer adhesion. It could be caused by issues with the printer’s setup, such as a dirty and unevenly balanced print bed, incorrect print parameters, or poor filament quality. Let’s look at a couple of options that will have your printer back up and running in no time.

To release PETG filament adhered to a glass bed, consider alternating between hot and cold conditions by heating or freezing the glass bed. Instead of printing PETG directly on a glass bed, treat it with a coating of adhesive, hairspray, or blue painter’s tape. These coatings give a layer that makes removing prints easier. A properly leveled bed with the nozzle not squishing onto the bed should solve the problem. For this reason, PETG should be laid down from a higher height than PLA. If the first layer of your nozzle goes deep into the print bed, your PETG print is likely to stick to the print bed. You can also try warming the print bed or using a flat instrument like a spatula to pull the print off. To avoid harming the glass bed, don’t use too much power with the spatula.

We hope you have enjoyed our recap of the top things that you need to know to properly 3D print when working with PETG filament! Reach out to Filamatrix today to gain access to an extensive stock of all different types of specialty filaments.

There’s so much to learn about 3D printing materials. Come and find out what to look for when examining the different densities of 3D printing filaments.

Those interested in 3D printing have a lot to learn on how to use the system properly. Find out what you need to know about 3D printing and humidity levels.

3D printing has many variables that both beginners and experts need to know. Find out what effects temperature has on 3D printer filament.

Get professional insights, industry news, and our latest deals