A Look at the Different Densities of 3D Printing Materials

There’s so much to learn about 3D printing materials. Come and find out what to look for when examining the different densities of 3D printing filaments.

844-810-1385

3D printing is a powerful player in today’s business world. It’s the type of technology that’s incredibly useful for quickly restocking supplies when needed. It has many uses and provides businesses with plenty of cost-cutting opportunities. The healthcare industry can utilize this technology to quickly generate 3D models of organs for educational purposes or to use in surgery.

Busy emergency rooms can also find 3D printing worthwhile because of its rapid prototyping abilities. There are many great things to learn about 3D printing in healthcare. Yet, all this speculation about 3D printing benefiting healthcare begs the question: how is 3D printing impacting the healthcare industry?

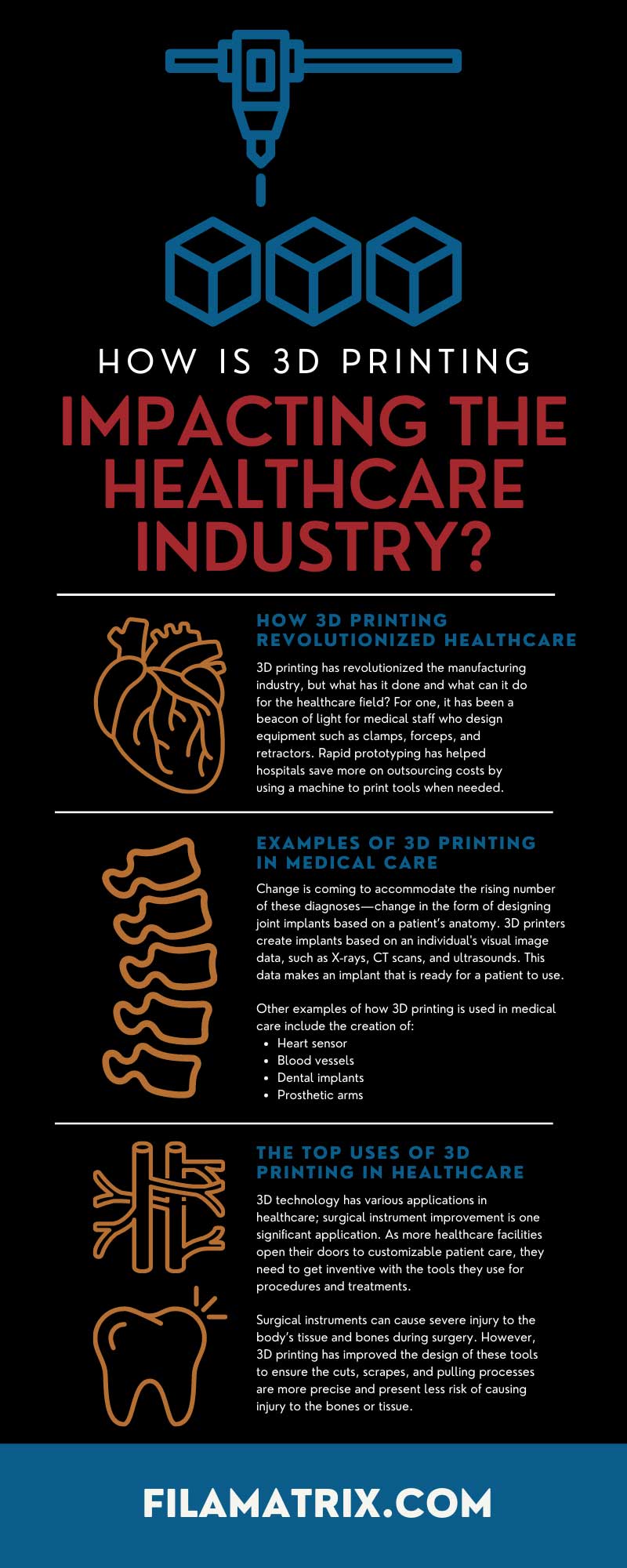

3D printing has revolutionized the manufacturing industry, but what has it done and what can it do for the healthcare field? For one, it has been a beacon of light for medical staff who design equipment such as clamps, forceps, and retractors. Rapid prototyping has helped hospitals save more on outsourcing costs by using a machine to print tools when needed.

Another area in which 3D printing has proven beneficial is prosthetic and implant creation. Dentists were the first to design implants using 3D technology. 3D tech helped specialists understand how to create implants and prosthetics based on a patient’s anatomy.

This technology has also enabled medical professionals to design prosthetic functionality using 3D printer filaments instead of hard rubber. These fibers help prosthetics function properly so that patients can heal better while continuing to live as they normally would.

One day, 3D technology could become the best way to design body parts for transplants. There are many patients awaiting heart, kidney, or tissue transplants, and doctors could eventually create these body parts using a patient’s cells and flexible material to form a replica. The process could subsequently decrease the number of patients waiting for a matching donor and improve the patient’s quality of life.

Currently, the process remains in the testing phase, with various reports stating the successful creation of human organs. One day, this technology could be used to help decrease the waiting time it takes to get a transplant.

Now that you understand the impact of 3D technology on the healthcare industry, let’s go over examples of 3D printing in medical care. One example that stands out is joint replacements. Many Americans are diagnosed with a musculoskeletal injury or disease every year.

Change is coming to accommodate the rising number of these diagnoses—change in the form of designing joint implants based on a patient’s anatomy. 3D printers create implants based on an individual’s visual image data, such as X-rays, CT scans, and ultrasounds. This data makes an implant that is ready for a patient to use.

Other examples of how 3D printing is used in medical care include the creation of:

3D technology has various applications in healthcare; surgical instrument improvement is one significant application. As more healthcare facilities open their doors to customizable patient care, they need to get inventive with the tools they use for procedures and treatments.

Surgical instruments can cause severe injury to the body’s tissue and bones during surgery. However, 3D printing has improved the design of these tools to ensure the cuts, scrapes, and pulling processes are more precise and present less risk of causing injury to the bones or tissue.

Other parts of the medical field seeing immense change are pharmaceuticals. Pharmaceutical companies have seen a slew of comments from patients desiring pills that won’t negatively interact with each other. A solution made possible by 3D technology is to create a drug that streamlines dosage requirements, specifically in regard to how many times a tablet must be taken each day and how many tablets should be taken at one time.

A 3D-printed tablet could safeguard patients by covering all symptoms of an ailment without causing extreme side effects from interacting with other medications. This process changes how patients take medications and how it is made.

There is much to learn about 3D technology in the medical field. Some changes to look forward to include decreased prices and wait times, both in the waiting room and at home for transplants, implants, and prosthetics. The other significant changes are better accessibility to healthcare and improvements to the complexity of operations.

Medical centers, hospitals, and specialty care facilities spend lots of money on acquiring supplies for their procedures, causing increased wait time for patients in and out of the waiting room. The better way to reduce the amount of time spent waiting is to find solutions, one of which is improving your technology.

Improvements in technology modernize the facility while also improving processing times, moving patients in and out of the exam room in less than an hour. 3D technology is demonstrating its usefulness in creating ready-to-use procedure tools. 3D printing allows doctors to rapidly print tools to cut down on costs for shipping and wait time for patients.

Many doctors want to improve access to affordable healthcare. This is another area where 3D printing technology is providing beneficial.

Medical specialists in around the world and in hospitals in the US have better and more immediate access to designing affordable and accessible healthcare options thanks to 3D technology. 3D technology has made it possible to create tools and low-cost medical equipment in communities and countries with limited access to healthcare.

There are many operations that doctors don’t feel comfortable doing because of the procedure’s low success rates and their own lack of experience. However, 3D printing has made it possible to train current and future medical professionals to identify and operate on specific human organs by designing replicas.

These replicas mimic real human organs, showing doctors and other specialists how to operate on different sections of the organ.

Though there are many benefits to this technology, it does still remain in the testing phase. While 3D printing is used on some occasions, it likely won’t become fully integrated into the field for at least 10 years. It’s a great technology, but it still needs improvements before its official debut.

The FDA is the gatekeeper of what’s acceptable to use in healthcare. 3D technology is great, but the FDA needs to set regulations on its use because it poses some risks to life and liability. While the FDA works to create these guidelines, healthcare professionals should approach the technology with care and awareness that even though it’s beneficial, it does come with risks.

Every medical facility using 3D technology needs to cut costs on buying supplies overseas, which is why they come to Filamatrix for USA-made 3D filaments. Explore our wide range of filaments to use in your medical facility to improve the quality of surgery and cut back on the cost and time it takes to get medical equipment.

There’s so much to learn about 3D printing materials. Come and find out what to look for when examining the different densities of 3D printing filaments.

Those interested in 3D printing have a lot to learn on how to use the system properly. Find out what you need to know about 3D printing and humidity levels.

3D printing has many variables that both beginners and experts need to know. Find out what effects temperature has on 3D printer filament.

Get professional insights, industry news, and our latest deals