A Look at the Different Densities of 3D Printing Materials

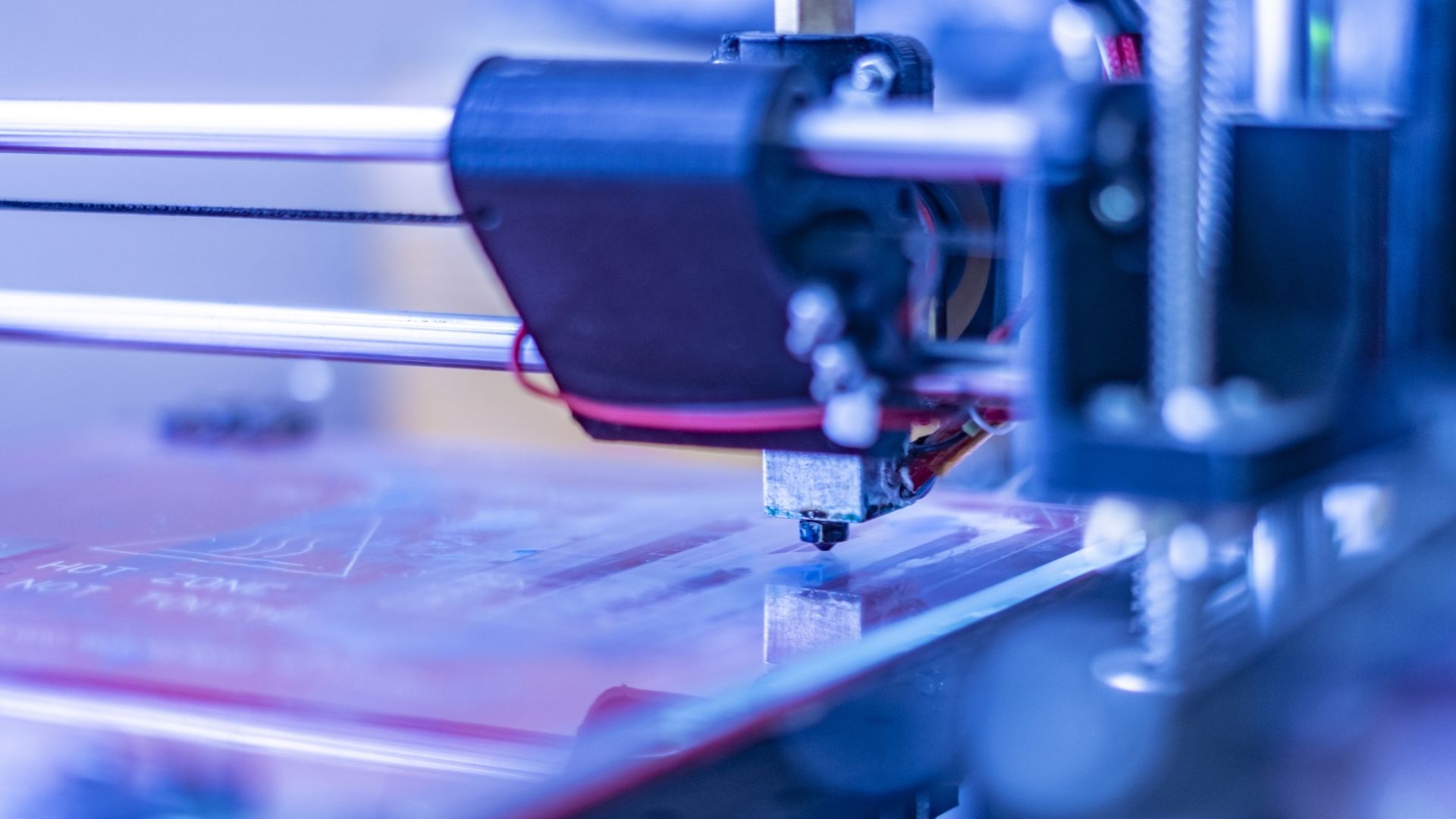

There’s so much to learn about 3D printing materials. Come and find out what to look for when examining the different densities of 3D printing filaments.

844-810-1385

3D printing is one of the most unique manufacturing processes to recently be conceived. While many will attest to the precision of the 3D printer as its most notable characteristic, many more will argue that the most notable characteristic is its resiliency throughout different fields. As such, here is how 3D printing can transform the electronic industry.

Increases Turnaround In Projects

In comparison to other manufacturing techniques, 3D printing is unusual in that the time and expenses involved in fabrication are independent of the complexity of the product. Instead, the weight of the materials being deposited in the device determines the lead time. As a result, prototype and completed product fabrication timeframes are extremely predictable. 3D printing reduces repetitive etching, pressing, drilling, and finishing operations during production of complicated electrical devices, notably multilayer PCBs. A fully-working board can be printed in less time than a traditional technique with the correct additive manufacturing technology and process. This enables designers and engineers to swiftly evaluate functionality issues and determine the need for redesigns, decreasing the time it takes to develop new devices.

Functional design and development techniques, whether for hardware and software, revolve around being adaptive to design changes. The first two advantages are crucial because they allow design teams to repeatedly evaluate design choices and assess whether redesigns are required. This also saves time and money by allowing design teams to quickly modify their products to changes in consumer tastes or client requirements. All this hinges on the capacity to analyze and prioritize complicated product redesigns fast, a process that would ordinarily take weeks with traditional PCB prototyping runs.

As more companies embrace an industrial mindset, 3D printing in consumer electronics manufacture will only grow more common. Consumer electronics will become more customized and modular as tooling requirements, fixed prices, and lead times are eliminated. Manufacturers will be able to develop consumer devices with a high mix and low volume, which represents a big opportunity. Because additive manufacturing technologies are intrinsically computerized, they can be seamlessly integrated into a fully digital, lights-out manufacturing environment. Manufacturing facilities will become more intelligent, autonomous, and productive as a result of this inherent digitization and new factory networking standards. These trends are likely to continue beyond consumer gadgets, according to manufacturers.

We hope this article has helped you understand how 3D printing can transform the electronics industry. The use of 3D printing in consumer electronics development is poised to alter how designers approach new electronic items and how businesses scale up to full production. If you are looking to purchase thermally conductive 3D printing filament, be sure to reach out to Filamatrix! Our products are great quality and come at an unbeatable price!

There’s so much to learn about 3D printing materials. Come and find out what to look for when examining the different densities of 3D printing filaments.

Those interested in 3D printing have a lot to learn on how to use the system properly. Find out what you need to know about 3D printing and humidity levels.

3D printing has many variables that both beginners and experts need to know. Find out what effects temperature has on 3D printer filament.

Get professional insights, industry news, and our latest deals