A Look at the Different Densities of 3D Printing Materials

There’s so much to learn about 3D printing materials. Come and find out what to look for when examining the different densities of 3D printing filaments.

844-810-1385

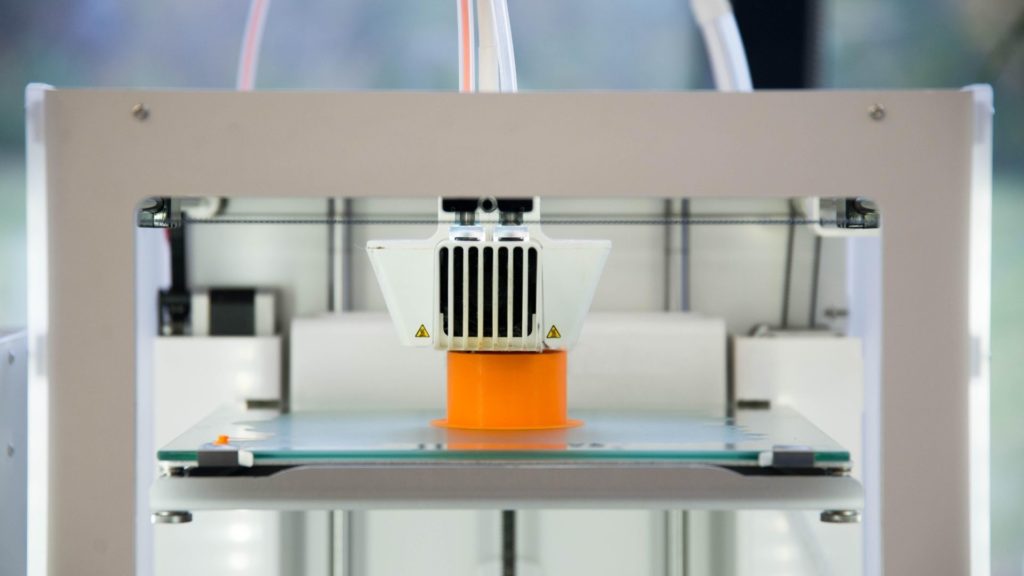

Thermally conductive filaments are some of the most groundbreaking materials in the modern 3D printing world. Allowing industries to use this technology in new ways, these resources create a wide range of opportunities that’s only limited by your imagination. However, despite this, conductive filaments are still only a small area of 3D printing, and it takes an additional expertise to use them effectively. Read our guide to getting started with conductive filaments in 3D printing to learn everything from what they are to what they can bring to your business.

To begin, conductive filaments are standard PLA materials infused with polymer substances that thermally conduct heat. Often made of nylon, these ingredients allow thermal energy to radiate through them, providing the filament with the same properties. This allows users to create products that have applications near heat sources without needing to account for potential damage.

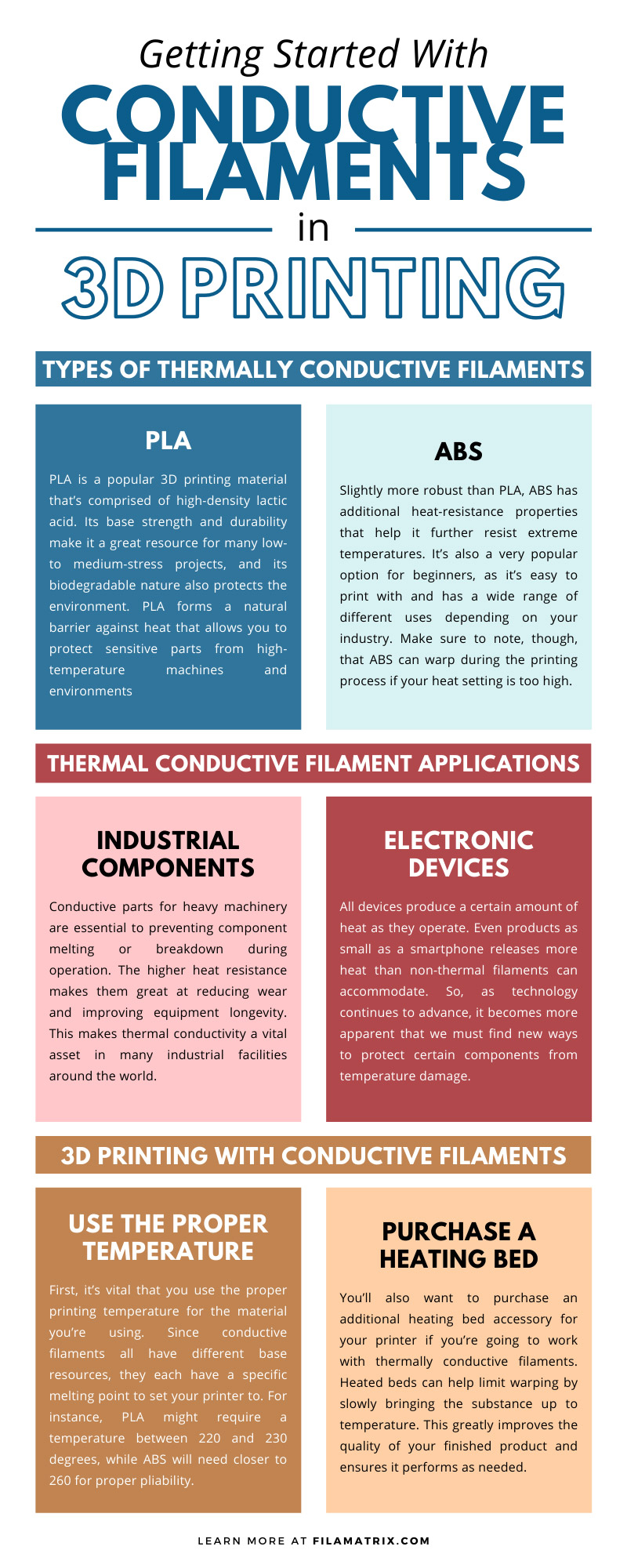

There are several types of conductive filaments currently on the market, and each comes with its own set of characteristics depending on its chemical makeup. As such, it’s important to understand each if you want to choose the best one for your specific project. These are some of the most common thermally conductive filaments you can purchase for your 3D printer:

PLA is a popular 3D printing material that’s comprised of high-density lactic acid. Its base strength and durability make it a great resource for many low- to medium-stress projects, and its biodegradable nature also protects the environment. PLA forms a natural barrier against heat that allows you to protect sensitive parts from high-temperature machines and environments. However, this material does have its limits, and you should never expose it to more than 54 degrees Celsius after extruding if you want it to maintain its structural integrity.

Slightly more robust than PLA, ABS has additional heat-resistance properties that help it further resist extreme temperatures. It’s also a very popular option for beginners, as it’s easy to print with and has a wide range of different uses depending on your industry. Make sure to note, though, that ABS can warp during the printing process if your heat setting is too high.

For those who need both strength and flexibility along with conductivity, nylon is the material for you. Thermal nylon is a filament variant that has a thermal conductivity of 4W/m-K. Nylon also has a natural temperature stability property that helps prevent warping while promoting optimal stiffness and durability. Just make sure you keep this material away from moisture as it can weaken the polymer and decrease its strength.

Now that you know what some of your filament options are, it’s important that you get an idea of how to use them. Conductive resources have a wide range of applications depending on the industry you’re in. This is especially true in fields that work with machines that produce a lot of heat. These are some of the most common functions to keep in mind.

Conductive parts for heavy machinery are essential to preventing component melting or breakdown during operation. The higher heat resistance makes them great at reducing wear and improving equipment longevity. This makes thermal conductivity a vital asset in many industrial facilities around the world.

These materials are also essential when manufacturing or protecting electronic devices. All devices produce a certain amount of heat as they operate. Even products as small as a smartphone releases more heat than non-thermal filaments can accommodate. So, as technology continues to advance, it becomes more apparent that we must find new ways to protect certain components from temperature damage. Otherwise, we not only risk overheating it, but also selling an item with a high fire hazard. As such, using conductive 3D filaments for the inner product casings helps protect both the device and the user from harm.

Conductive filaments also help with products that release a steady amount of heat over time. Mechanical sensors send signals back to a control panel by releasing a burst of electricity along with it. This heats up the component and sustains the temperature during its entire period of operation. Using conductive materials around these casings helps safely release this access heat without while keeping the device protected. This promotes optimal safety and functionality while the product is in use.

If you’re really interested in getting started with conductive filaments in 3D printing, it’s important that you know how this process works. Printing with these materials comes with its own set of unique challenges to account for during the creation process. Otherwise, you risk increasing your margin for error and making parts that are below your functional standard. Here are some helpful tips to remember.

First, it’s vital that you use the proper printing temperature for the material you’re using. Since conductive filaments all have different base resources, they each have a specific melting point to set your printer to. For instance, PLA might require a temperature between 220 and 230 degrees, while ABS will need closer to 260 for proper pliability. So, pay close attention to the manufacturer’s guidelines and make sure your printer can accommodate that need.

You’ll also want to purchase an additional heating bed accessory for your printer if you’re going to work with thermally conductive filaments. Heated beds can help limit warping by slowly bringing the substance up to temperature. This greatly improves the quality of your finished product and ensures it performs as needed.

Filamatrix offers a series of different conductive 3D printer filaments for a large array of industry applications. Though, we stand by our Thermal Nylon as being one of the best for this purpose. This material offers a structural stability that withstands temperatures above 150 degrees Celsius and non-insulating properties to conduct electricity. As such, we’re confident that it can achieve the results you’re looking for and accommodate any type of application. Visit our website or give us a call for more information.

There’s so much to learn about 3D printing materials. Come and find out what to look for when examining the different densities of 3D printing filaments.

Those interested in 3D printing have a lot to learn on how to use the system properly. Find out what you need to know about 3D printing and humidity levels.

3D printing has many variables that both beginners and experts need to know. Find out what effects temperature has on 3D printer filament.

Get professional insights, industry news, and our latest deals