A Look at the Different Densities of 3D Printing Materials

There’s so much to learn about 3D printing materials. Come and find out what to look for when examining the different densities of 3D printing filaments.

844-810-1385

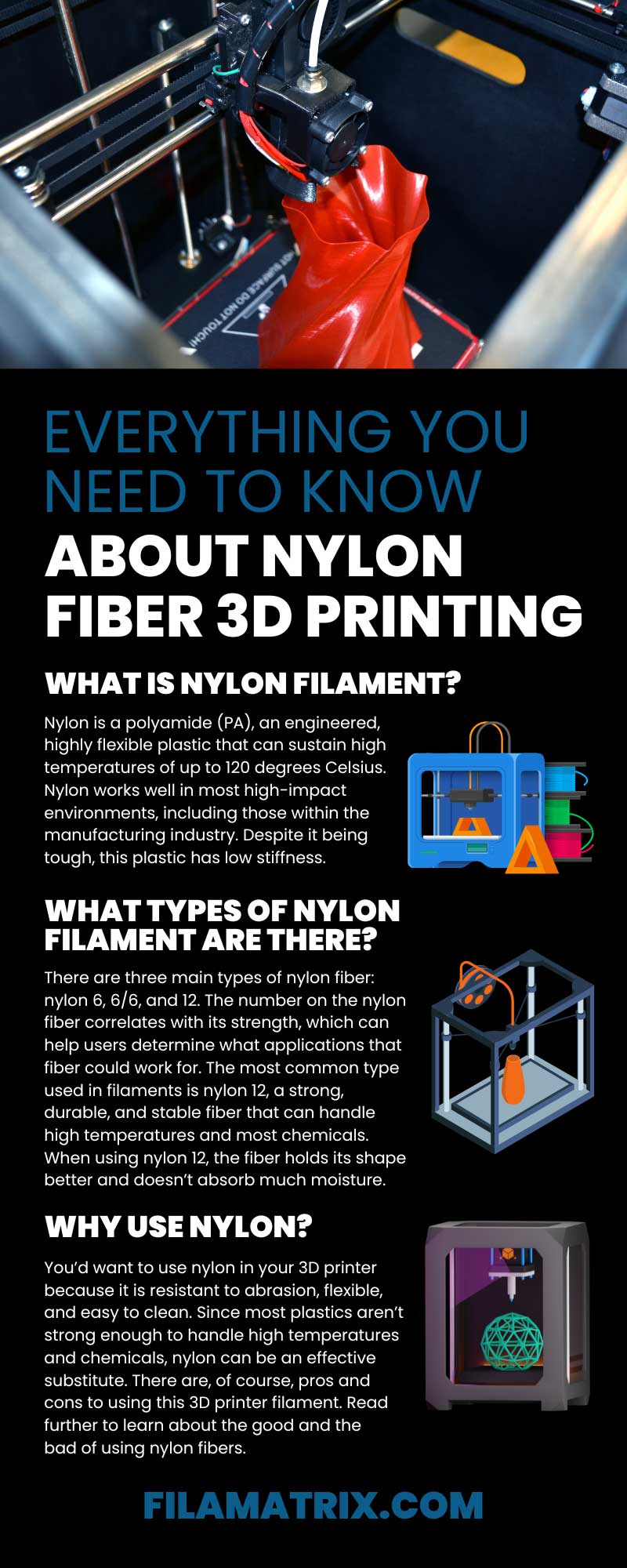

3D printing with nylon fiber is different than printing with PLA. Both filaments work well, but some types of nylon warp from temperature changes in the extruder or surrounding environment. Before you start using nylon fiber in 3D printing, you should learn everything you need to know about the filament.

Nylon is a polyamide (PA), an engineered, highly flexible plastic that can sustain high temperatures of up to 120 degrees Celsius. Nylon works well in most high-impact environments, including those within the manufacturing industry. Despite it being tough, this plastic has low stiffness.

Nylon has many properties, including being hygroscopic or susceptible to warping. However, one of nylon’s more positive properties is its high resistance to alkali and oil. Additionally, it has tremendous abrasion resistance.

There are three main types of nylon fiber: nylon 6, 6/6, and 12. The number on the nylon fiber correlates with its strength, which can help users determine what applications that fiber could work for. The most common type used in filaments is nylon 12, a strong, durable, and stable fiber that can handle high temperatures and most chemicals. When using nylon 12, the fiber holds its shape better and doesn’t absorb much moisture.

You’d want to use nylon in your 3D printer because it is resistant to abrasion, flexible, and easy to clean. Since most plastics aren’t strong enough to handle high temperatures and chemicals, nylon can be an effective substitute. There are, of course, pros and cons to using this 3D printer filament. Read further to learn about the good and the bad of using nylon fibers.

One advantage nylon brings to the table is its mechanical property. Compared to other fiber types, nylon has checked off many boxes for production needs, including abrasion resistance, excellent performance in high temperatures, and beneficial flexibility.

There are downsides to this filament that businesses should keep in mind. One con to consider is that this plastic can absorb moisture in the air if you fail to properly contain it. Before you can work with nylon, you need to ensure that the room is not too warm and that you’re precisely following the printer setting temperature. Additionally, you will need to pre-dry nylon before using it to avoid moisture buildup.

Nylon, like other filaments, has its issues, but these problems are preventable. Before you can solve your 3D printing challenges, you first need to recognize the source of the problem. Here are three common issues with 3D printing nylon filaments and suggestions that can help you prevent these problems from escalating.

Storage might be a problem if you don’t have adequate space in your warehouse to safely house nylon. Nylon cannot remain in the open for too long because it can absorb moisture. Prevent poor-quality prints by keeping nylon in a special area, such as an air-tight container. The entire spool must stay in an air-tight container between uses to prevent damp filaments.

Warping is a common 3D printing filament common issue that is even more likely to occur in nylon fiber. Even if you have the best storage solutions, warping can still occur if you’re not careful. Always place the spool inside an enclosure before you start printing. When inside the compound, follow the user manual to understand what temperature to set the printer at before using it. Use a heated bed to diminish the chance of severe warping; a heated bed controls the temperature throughout the process.

The first layers won’t always be the best when working with this fiber type. You may not always have access to an enclosure to stop the filament from working and wrecking the first layer. Instead of an enclosure, you could use brims and rafts. Brims and rafts assist in layering the bottom layers by adding loops—these loops help hold the edges of your design. This, combined with an appropriate build plate material like garolite or glass and possibly a bit of a PVA glue stick, increases the likelihood of success with your first layer.

Multiple industries rely on nylon, with manufacturing being one of the few that uses it constantly to make flexible parts that can handle harsh environments. You can find manufacturers 3D printing nylon fibers into different machine parts, including nuts, gears, and bearings.

Printing with nylon requires specific settings for the bed, extruder, and speed. You might have questions about how to achieve the highest-quality prints with this new filament. Start the process of setting up your 3D printer for nylon by learning the recommended settings for extruder and bed temps.

The extruder temperature may vary depending on the brand and type of nylon used. For instance, say you use a 3D printer carbon fiber filament from Filamatrix in the printer. The recommended extrusion temperature setting for the nozzle is 255 degrees Celsius. Meanwhile, you will want a bed temperature of 70 degrees Celsius, but it should dry at 75 degrees Celsius.

You should not use a fan at all when printing with nylon. Nylon cools fast, and with a fan blowing hot air around, the fiber’s layers may begin to warp, creating unattractive edges. Focus only on the printer speed; you don’t need a fan. You should aim to keep the printer speed between 30 to 150 mm/s.

You can use a glass or garolite hotbed with adhesive to achieve the best results. Keep in mind that the fiber heats up fast and can clog the machine, so you will want to use a nozzle with a strong casing to avoid clogging the nozzle.

You can find nylon fibers across online stores and in stores near you. But if you want a specialized seller that’s a leading expert in 3D printing filaments, reach out to Filamatrix. We are a leading brand selling filaments made right here in the USA.

After learning everything you need to know about nylon 3D printing filaments, it’s time to explore your filament options. Nylon is one of our best sellers, and it’s one we highly recommend to manufacturing companies with large warehouses needing material that can handle susceptible environments. Reach out to us with any questions about our nylon filaments.

There’s so much to learn about 3D printing materials. Come and find out what to look for when examining the different densities of 3D printing filaments.

Those interested in 3D printing have a lot to learn on how to use the system properly. Find out what you need to know about 3D printing and humidity levels.

3D printing has many variables that both beginners and experts need to know. Find out what effects temperature has on 3D printer filament.

Get professional insights, industry news, and our latest deals