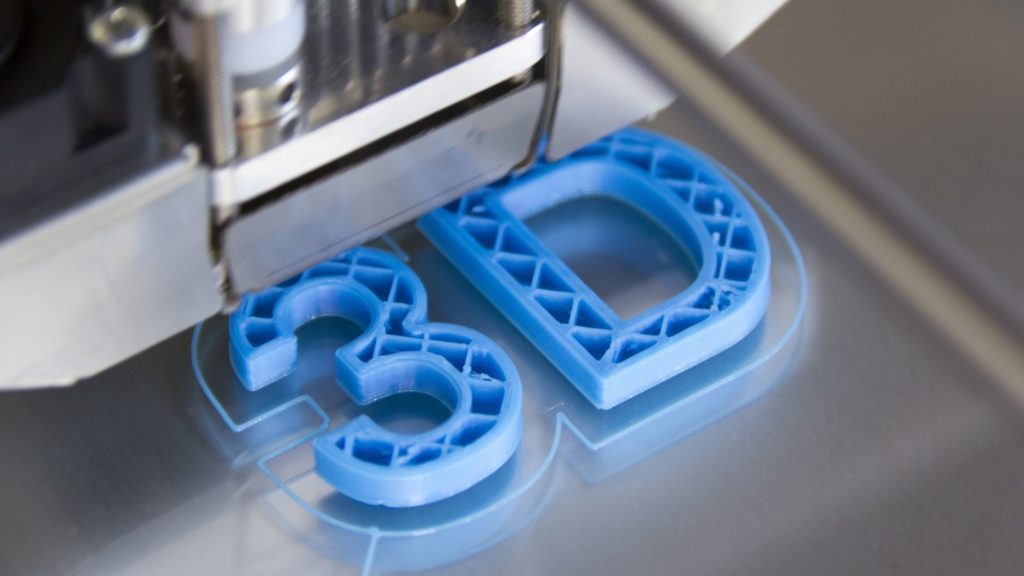

A Look at the Different Densities of 3D Printing Materials

There’s so much to learn about 3D printing materials. Come and find out what to look for when examining the different densities of 3D printing filaments.

844-810-1385

In 3D printing, extrusion is the process of pushing your filament through the printing nozzle and into the desired alignment. However, should these materials move through the printer too quickly, it can leave a series of errors along your finished product such as dimensional inaccuracies and residual strings. Known as over-extrusion, this is a common problem for even experienced 3D printing professionals. As such, understanding a few solutions is crucial to your continual success. Use our four ways to fix over-extrusion in your 3D prints to protect your projects.

If you notice that your 3D printer extrudes more material than necessary during a print, one of the first things you should check is its temperature settings. Every filament has a recommended extruding temperature that ensures it reaches the proper mailable state. But, when the heat is too high, it can melt your material, causing it to push through the nozzle at a faster pace. Because of this, make sure you double-check your set temperature and lower it if necessary.

Slightly adjusting your filament’s dimensions in your printer settings is also an effective way to fix over-extrusion in your 3D prints. When the registered diameter of your material is larger than that of the substance itself, it allows the printer to extrude faster than intended. As such, creating the proper balance of pressure is important to releasing filament at a controlled rate. So, try dialing down this setting in your printer to see if it makes a difference.

Likewise, you may need to change your printer’s extruding nozzle for the same reason. If it’s too large for the dimensions of your filament, it won’t be able to control how fast the extruding process is during a project. For this reason, if changing your dimensions in the printer settings doesn’t work, the next step should be to switch to a smaller nozzle size.

While you’re checking your printer’s settings, another thing you can do is reset its flow rate or extrusion multiplier. This number represents the amount of material extruded at a given time. When this number is too high, your printer will automatically release too much filament for your design and over-extrude the layers of your print. Make sure you test this flow rate in small intervals to ensure it’s where you need it.

Along with troubleshooting any printer issues, using the right materials is the key to creating the perfect print every time. That’s why we at Filamatrix work hard to provide quality flame retardant 3D printer filaments. These substances help reduce the risk of extrusion by maintaining a semi-solid form—even when exposed to high heat. They also provide a lowered chance of warping and an increased amount of layer adhesion. If you’re interested, give us a call to learn more.

There’s so much to learn about 3D printing materials. Come and find out what to look for when examining the different densities of 3D printing filaments.

Those interested in 3D printing have a lot to learn on how to use the system properly. Find out what you need to know about 3D printing and humidity levels.

3D printing has many variables that both beginners and experts need to know. Find out what effects temperature has on 3D printer filament.

Get professional insights, industry news, and our latest deals